38 aiag process flow diagram

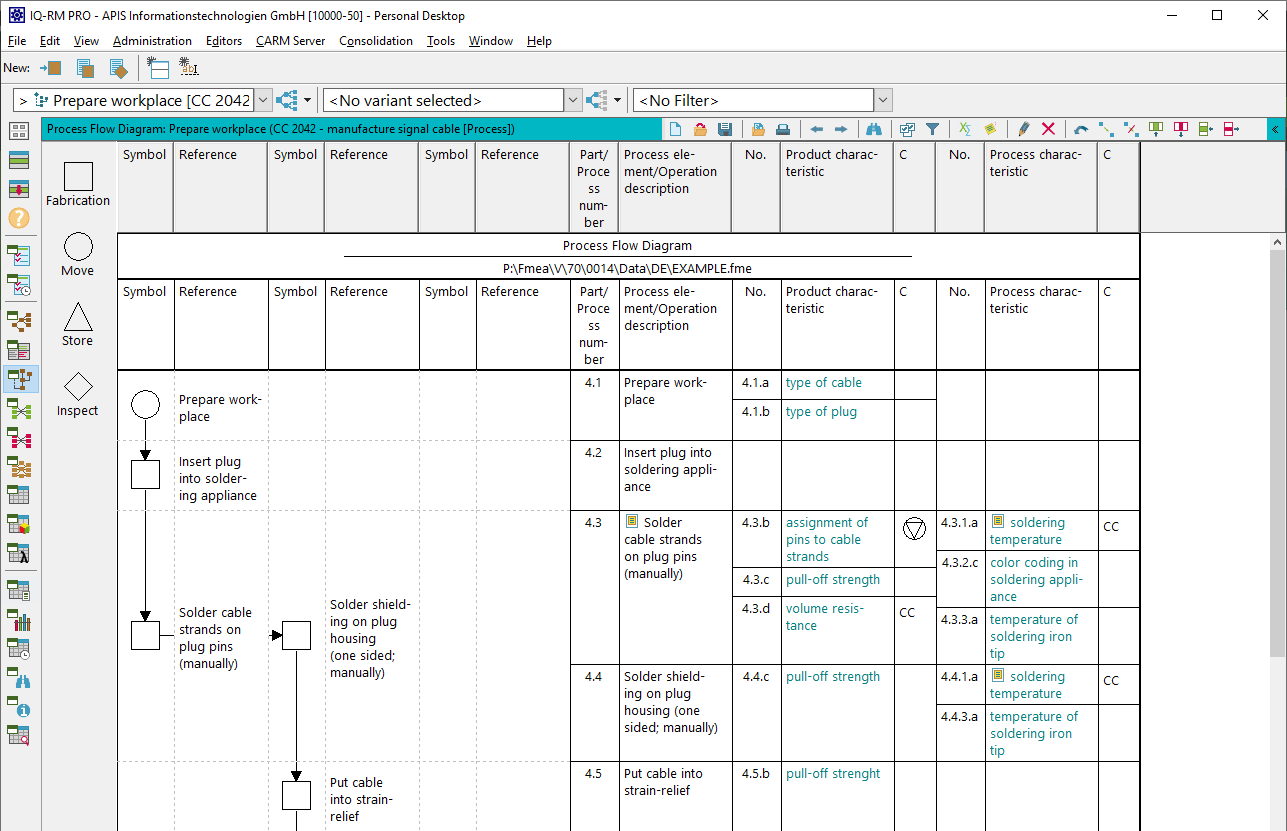

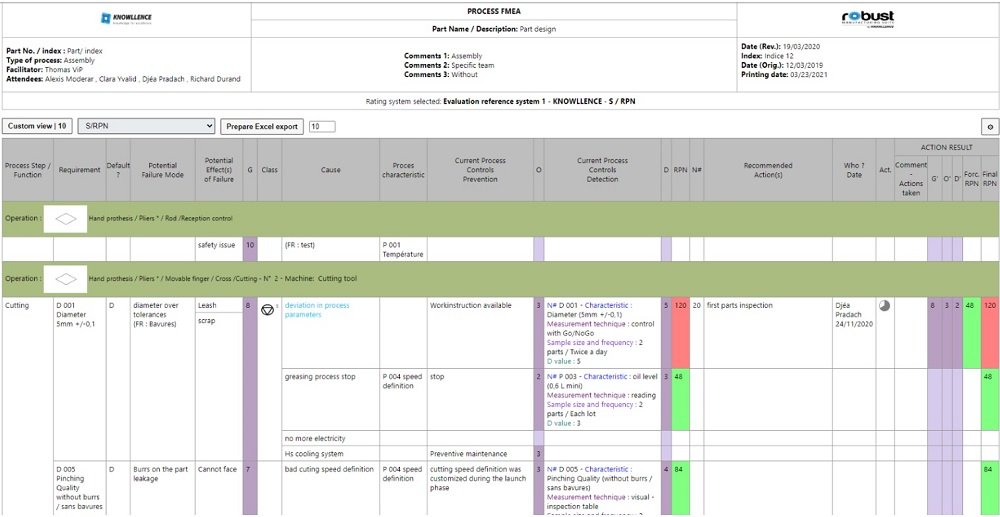

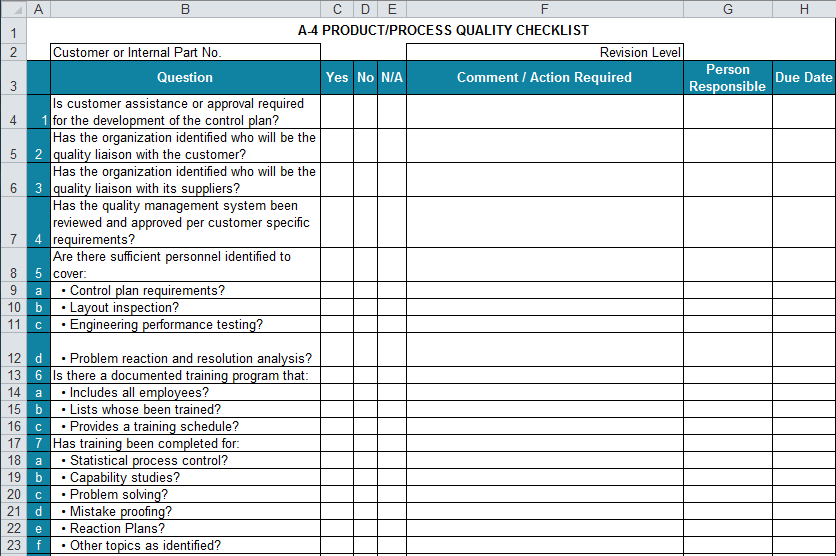

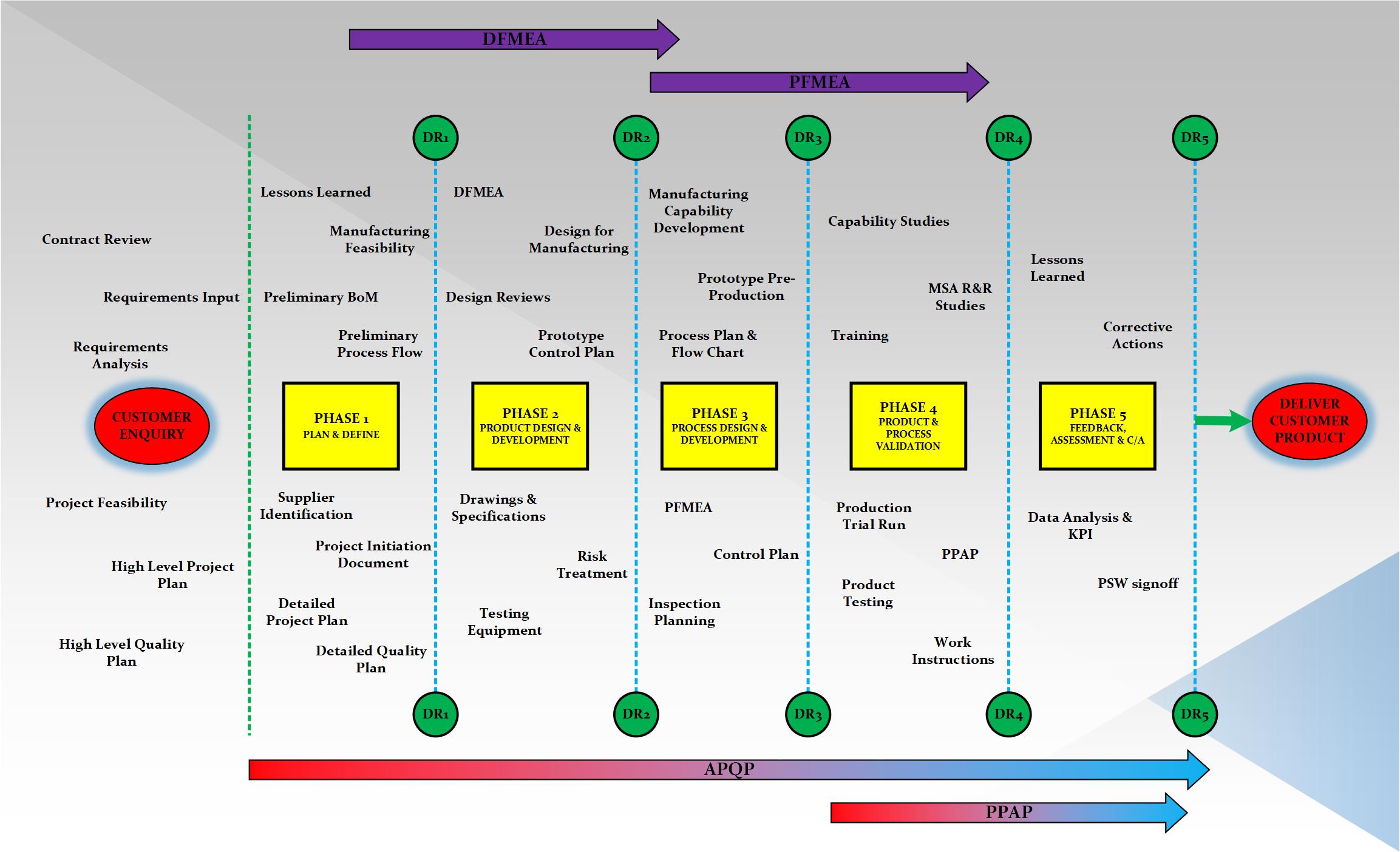

3 Process Flow Diagram N/A N/A S Any Standard flowchart format Indentifies all process steps from receiving to shipping. Process steps must match PFMEA and Control Plan steps. 4 Process Failure Mode & Effects Analysis (PFMEA) N/A N/A S Can be Alto - Shaam supplied format or an AIAG compliant PFMEA. Process steps must match Process Flow Chart ... Completing our free self-assessment is the first step in mastering the Automotive Quality Core Tools. This online survey tests basic competency in each of the Core Tools to help evaluate your current understanding of APQP/PPAP, FMEA, MSA and SPC, and determine opportunities for additional training.

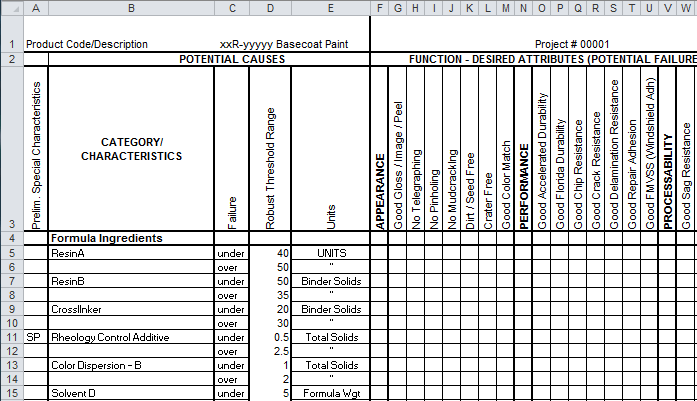

Process Flow Diagram PFMEA Control Plan Product-Process Change 4th Design Matrix 4th Bulk Materials Reqts 4th Performance Test Results 4th ... (Process FMEA) AIAG Fourth Edition SAE J1739 Insert FMEA# Name/number of item Responsibility: Model Years: model years/programs FMEA Date: Team members Process Step

Aiag process flow diagram

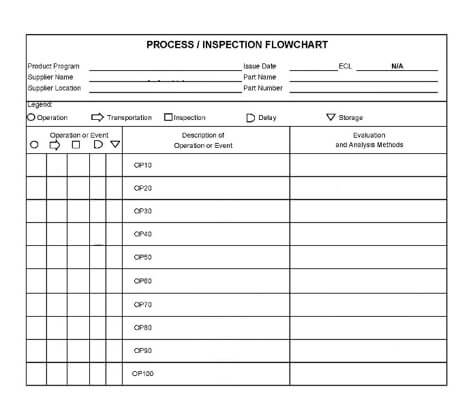

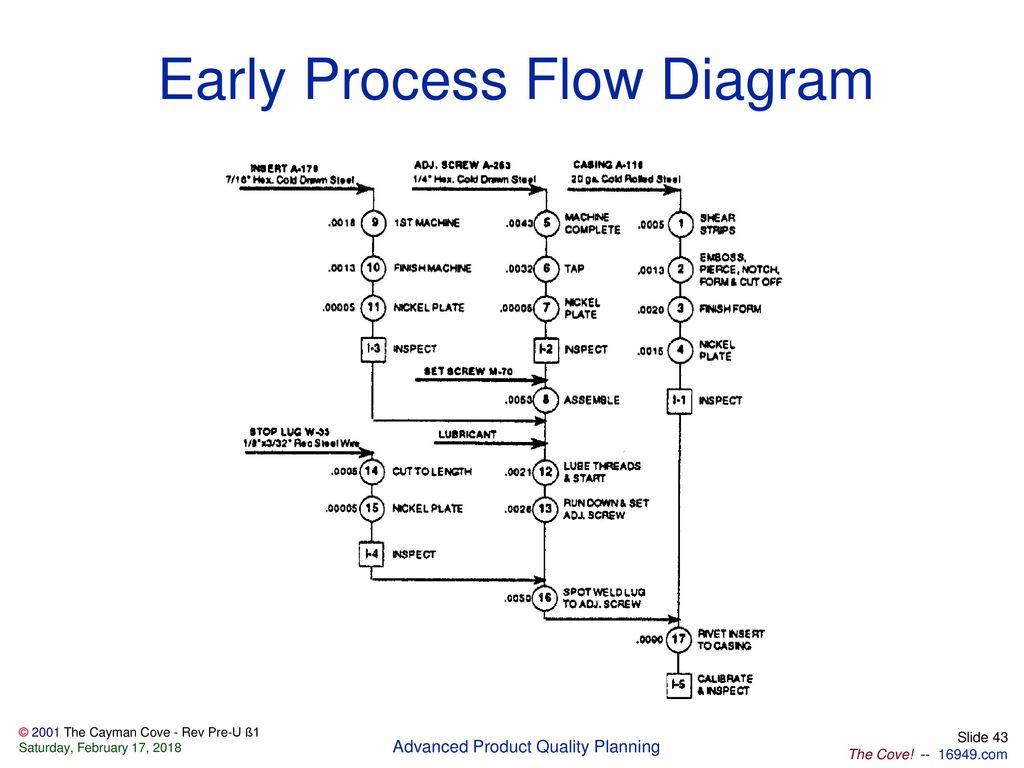

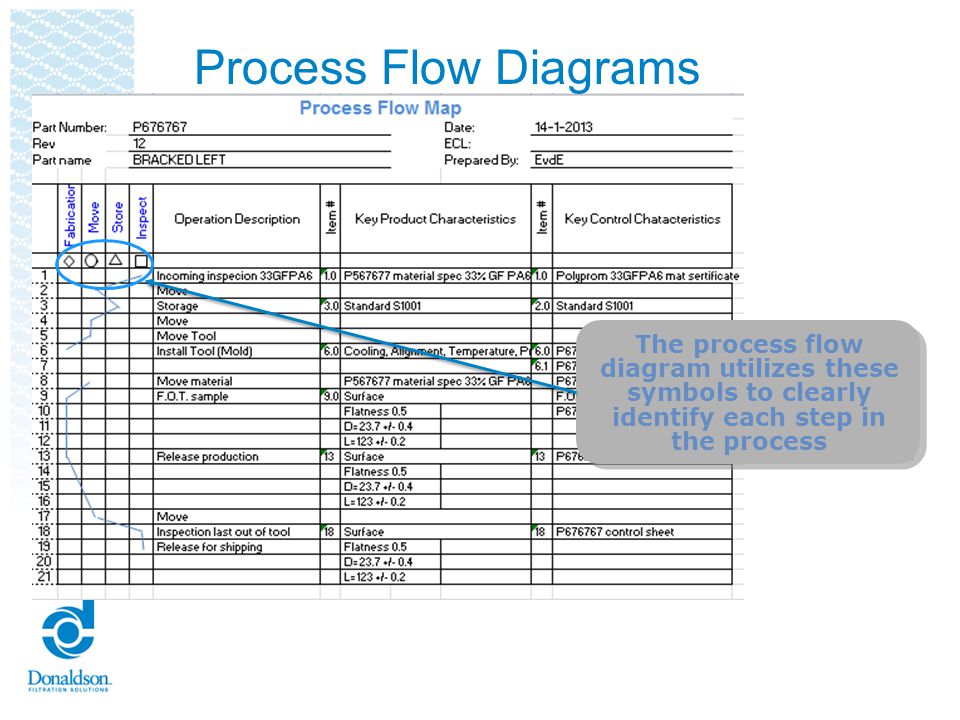

5.Process Flow Diagrams R R S * R 6.Process FMEA R R S * R 7.Control Plan R R S * R 8.Measurement System Analysis studies R R S * R 9.Dimensional Results R S S * R 10.Material, Performance Test Results R S S * R 11.Initial Process Studies R R S * R 12.Qualified Laboratory Documentation R S S * R 13.Appearance Approval Report (AAR), if ... This encompasses alternate process flows and movement of product to and from external operations. Note 1: Within the process flow diagram, there shall be sufficient detail of the production process steps and sequence. Note 2: Process flow diagrams for families of similar parts are acceptable if the new 62. Location: Greater Milwaukee USA. That is an old school diagram that General Motors required from suppliers back in the 80s. It was a few years before AIAG standardized the Control Plan format, so this was a combined process flow and control plan. This was before you could do this easily on a computer.

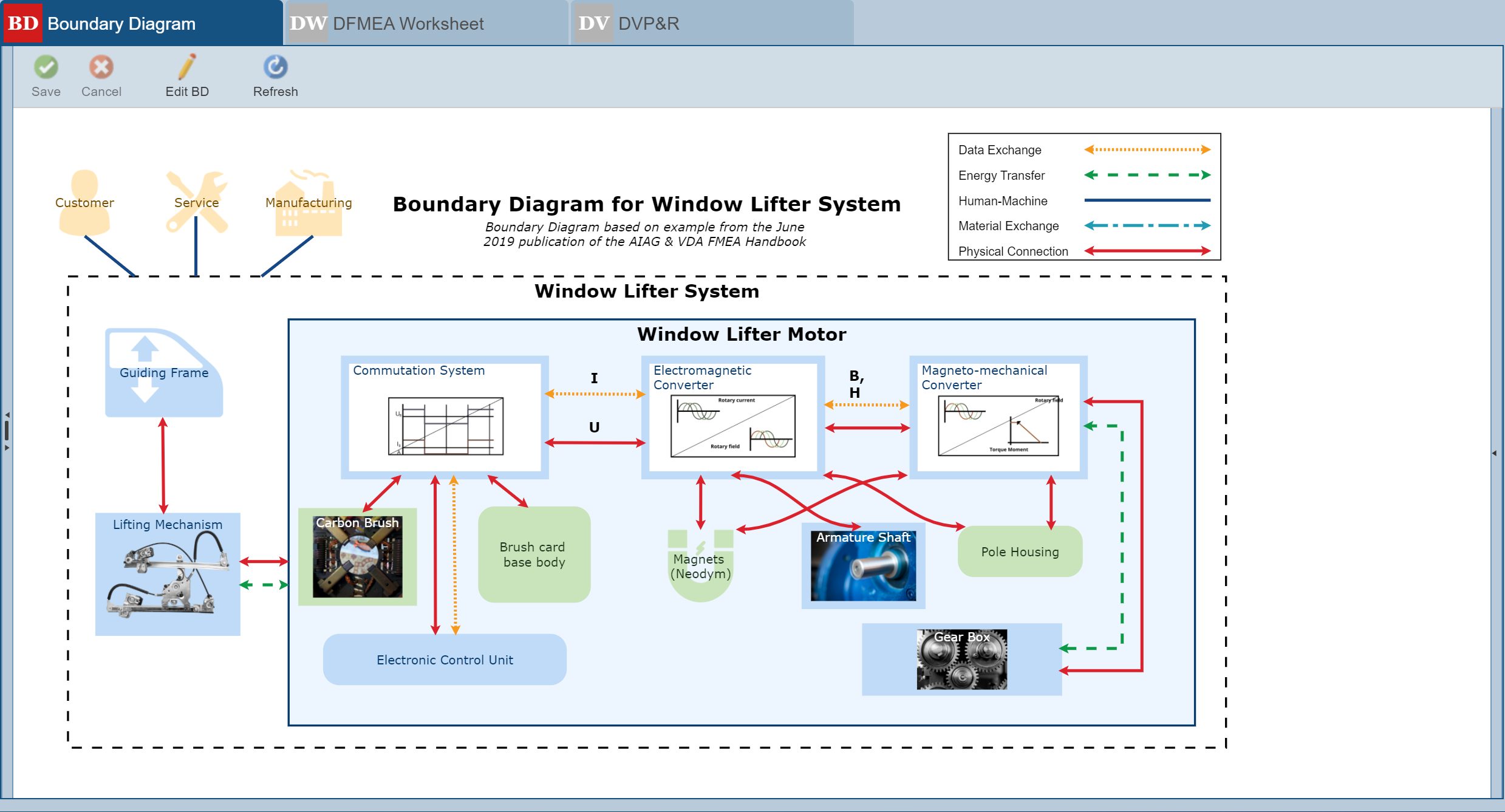

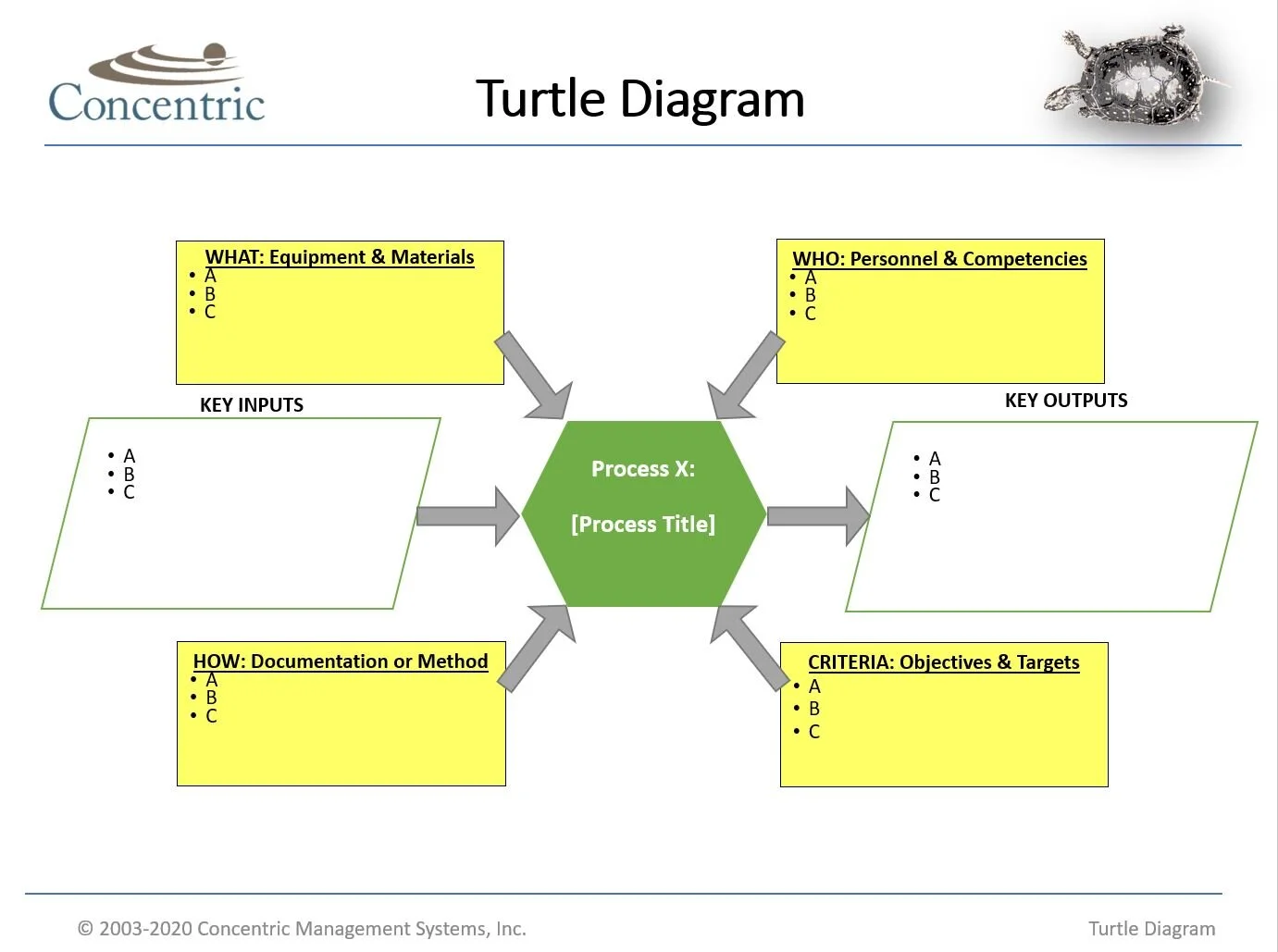

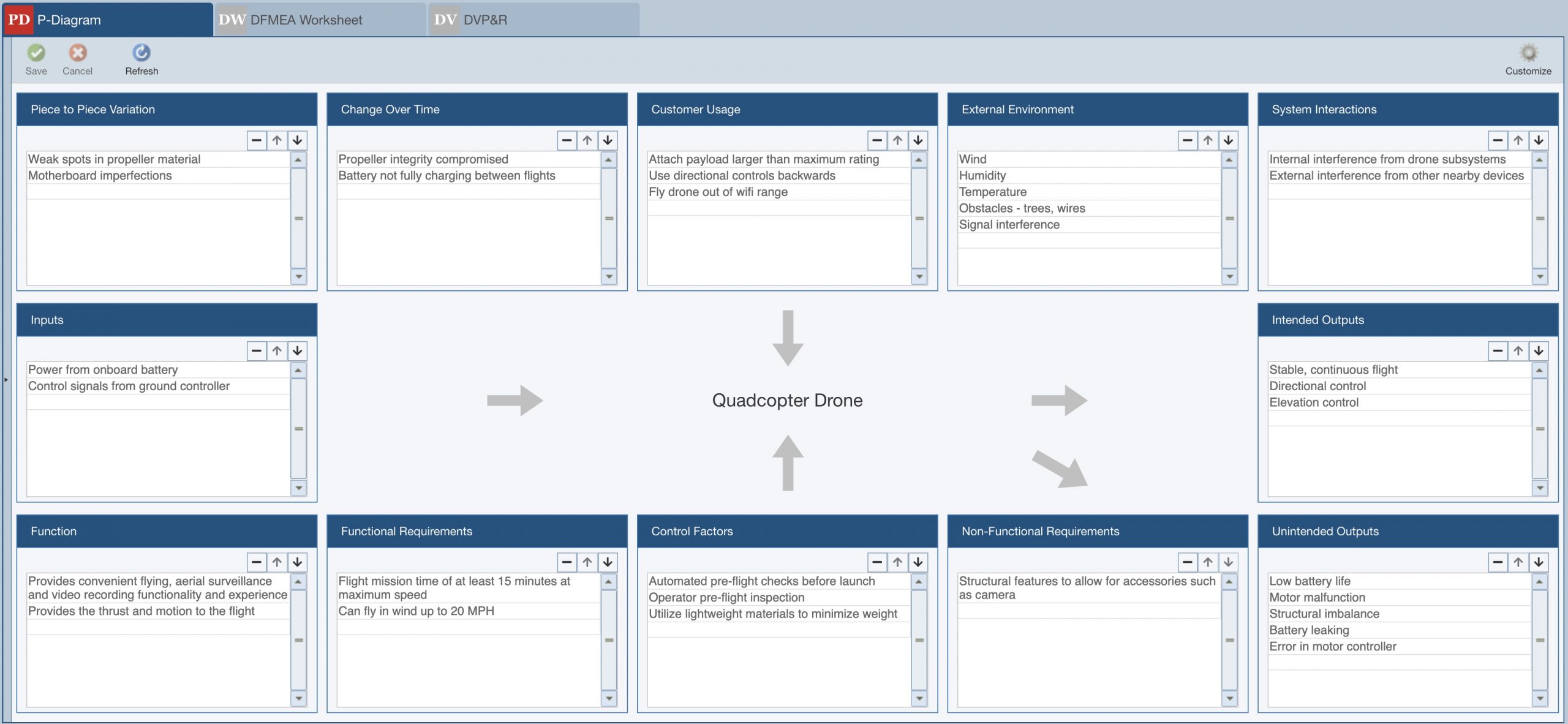

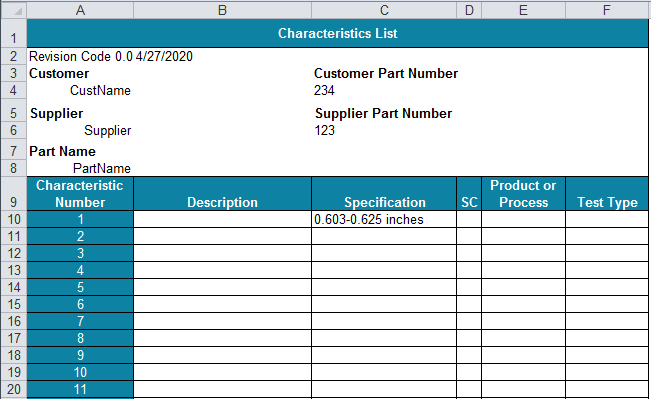

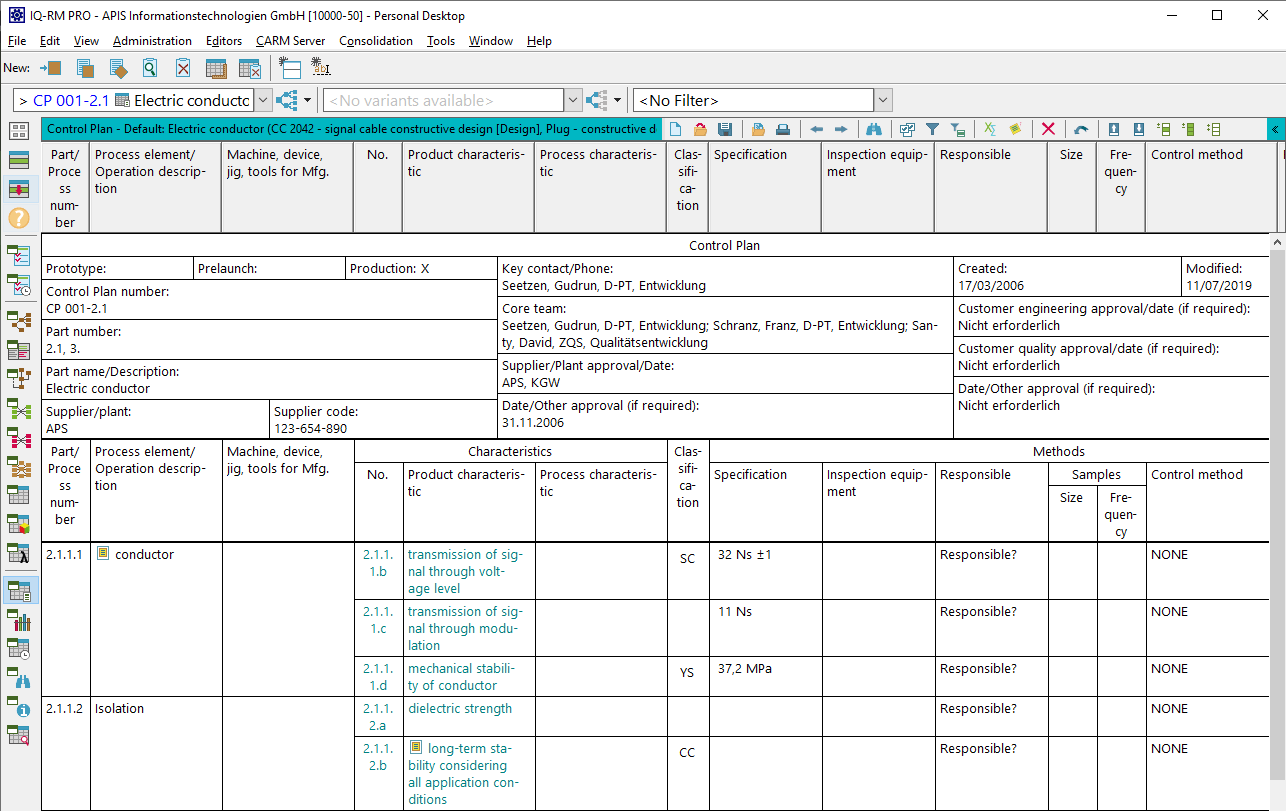

Aiag process flow diagram. Process Flow Diagrams z The Process Flow Diagram provides a logical (visual) depiction of the ... James Davis, GDLS Slide Number: 12 12. z. The SAE/AIAG PFMEA guidelines describe two methods of defining process functions. Either or both may be used. z. Process Functions may be described in terms of: The product features/characteristics that are ... 3. Process Flow Diagram 4. Process FMEA 5. Control Plan 6. Measurement System Analysis 7. Initial Process Studies 8. Packaging, Preservation, and Labelling Approvals 9. First Article Inspection Report 10. Customer Specific PPAP Requirements . Note: "No" selections in Section 13a require an Action Plan item documented in Section 14 below . 14 ... The Automotive Industry Action Group (AIAG) has standards for completing this form Supplier company name Part number Revision level Part name Name and telephone number of the key contact Date of the latest control plan updates. All the steps in the manufacturing process that are relevant to the control of the product quality. •Process flow diagram. 888-336-1124 | www.qualitysupportgroup.com ... characteristics to functions •Tools: •Function analysis tree •Parameter diagram Source: AIAG / VDA FMEA Handbook. 888-336-1124 | www.qualitysupportgroup.com ... •From current FMEA processes and methods to the new AIAG VDA FMEA process and tools •Use existing FMEAs ...

6. Process Flow Diagram 7. PFMEA 8. Control Plan 9. Measurement Systems Analysis (MSA) 10. Dimensional Results 11. Material, Performance Test Results 12. Initial Process Study (Cpk) Capability Studies 13. Qualified Laboratory Documentation 14. Appearance Approval 15. Sample Product Parts 16. Master Sample(s) 17. Checking Aids 18. SLTN ... NOTE 2: For bulk materials, see Appendix F. 2.2.5 Process Flow Diagram(s) The organization shall have a process flow diagram in an organization-specified fomat that clearly I describes the production process steps and sequence, as appropriate, and meets the specified customer needs, requirements and expectations (e.g., Advanced Product Quality ... the Process Flow steps, and indicates "what could go wrong" during the fabrication and assembly of each component. 7 -Control Plan Process Flow Diagram, also known as a process flow chart, shows the document and clarifies all steps required in the manufacturing of the part in question. ICAR 1748 (GM Process Audit ) and ICAR 1844 (GM Process Audit) 01-01-17 22.0 Added The number of distinct categories (ndc) the measurement process can be divided into shall be greater than or equal to 5. AIAG MSA 4th ed. requirement Removed: ^A Gage R&R templateis included in Supplier PPAP Pack Forms _ Template is Long Gage Study, want to

Aiag Process Flow Diagram Template. dannie.bins May 15, 2021 Templates No Comments. 21 posts related to Aiag Process Flow Diagram Template. Free Process Flow Diagram Template. Process Flow Diagram Unique Work Flow Chart Template Powerpoint Unique Basic Flowchart Symbols. 8.6 Requirement 5: Process Flow Diagram 14 8.7 Requirement 6: Process Failure Mode and Effects Analysis (PFMEA) 14 8.8 Requirement 7: Control Plan 14 8.9 Requirement 8: Measurement System Analysis Studies (MSA) 15 9.0 Requirement 9: Dimensional Results 15 9.1 Requirement 10a: Material Test Report 15 Process Flow Diagram. The Process Flow Diagram outlines the entire process for assembling the component or final assembly in a graphical manner. The process flow includes incoming material, assembly, test, rework and shipping. Process Failure Mode and Effects Analysis Process flow diagrams - concentric The AIAG APQP Manual process flow chart is a [ ] Products. than individual steps in the process. The flow chart assists the organization s product . Aiag process flow chart doc - books reader Aiag Process Flow Chart downloads at Booksreadr.org AIAG Product Part Approval Process (PPAP) Manual. AIAG Advanced ...

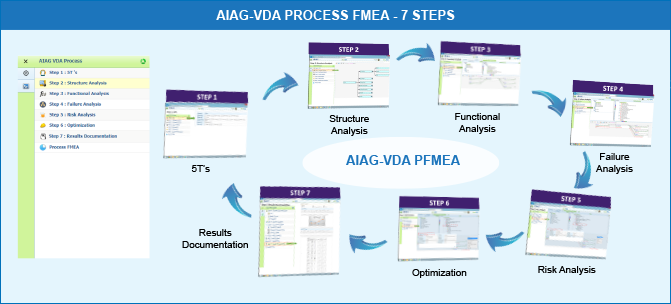

The information provided by the Process Flow Diagram into the Structure and Function Analyses is placed in the PFMEA columns in the same manner that it would have been if the information was transferred directly to the PFMEA from the Process Flow Diagram as it is done when using the AIAG 4 th Edition PFMEA methodology.

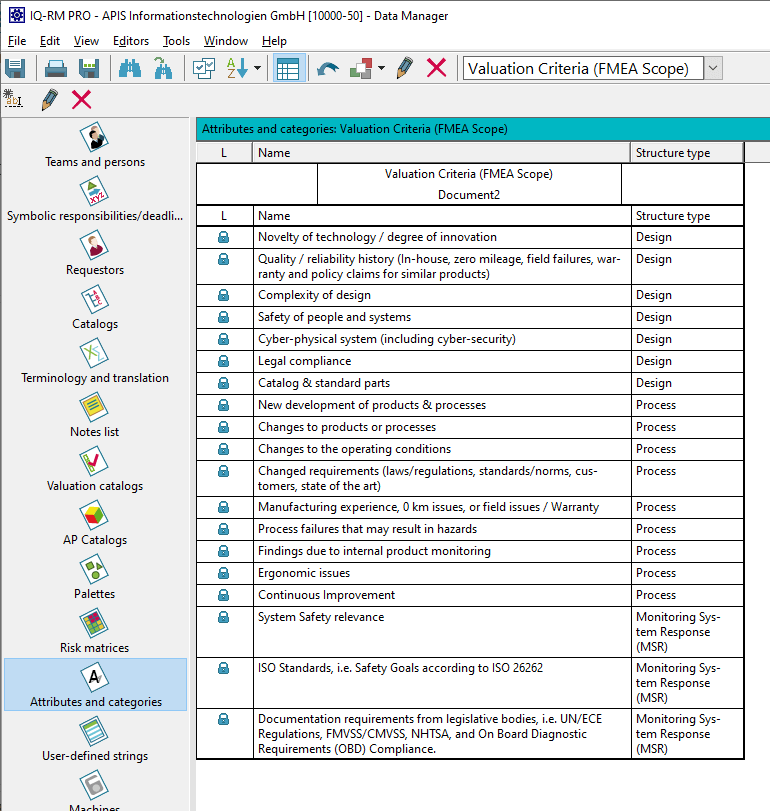

- 7 PFMEA PFMEA AIAG & VDA 1st June 2019 Step 1 Planning and Preparation - - Process Flow Chart Layout - - Characteristics Product - Process Flow Chart Layout - 4M - Characteristics Process - Characteristics Matrix Product & Process Step 2 Structure Analysis 2.1 , , 2.2 2.3

The AIAG - APQP Manual (Second Edition), section 3.3 states, "The process flow chart is a schematic representation of the current or proposed process flow. It can be used to analyze sources of variation of machines, materials, methods, and manpower from the beginning to end of a manufacturing or assembly process.

Production Part Approval Process (PPAP) is the industry standard that ensures engineering design and product specification requirements are met. Through the PPAP guideline, suppliers and customers understand the requirements to obtain part approval of supplier manufactured parts. Applicable to all parts and commodities, application of these ...

2.2.5 Process Flow Diagram Assessment "Process Flow Diagram is a representation of the process flow." Diagram accurately reflects process, rework, and inspection. All stations shall be identified that create Required, Design and Process Characteristics and shall match

In the development of the process flow chart, was the DFMEA used if available to identify specific characteristics that may be critical? 3 Is the flow chart keyed to product and process checks in the control plan and PFMEA? 4 Does the flow chart describe how the product will move. i.e., roller conveyor, slide containers etc.? 5

Most of all, get hands-on real-world experience working with AIAG-VDA PFMEA, Process Flow (Structure Analysis), and Control Plan at our Open Enrollment or at your product onsite. This 1-day seminar addresses all of the elements of the Process Failure Mode Effects Analysis (PFMEA) and Control Planning process and defines it as a process within ...

Initial process flow is complete; used to develop PFMEA and Control Plan. AIAG checklist A-6 or equivalent initiated and open issues identified with actions. Process Flow complete and AIAG A-6 checklist or equivalent complete with no open issues. Launch containment is addressed in flow. Process Flow complete and AIAG A-6

In the AIAG 4th edition of the PPAP book page ii shows a PPAP Process Flow Diagram in a pictorial format - and please remember the AIAG is a suggested set of guidlines to follow and in some cases are fully accepted by our customers and in other cases they are less interested in having a specific format.

1. Process Flow Diagram, 2. Process Failure Mode and Effect Analysis (PFMEA), 3. Control Plan, 4. Design Failure Mode and Effect Analysis (DFMEA), 5. Statistical Process Control (SPC), 6. Measurement System Analysis (MSA), 7. Production Part Approval Process (PPAP) and. 8. Advanced Product Quality Planning (APQP). The course material is in line ...

The process flow chart is a schematic representation of the current or proposed process flow. It can be used to analyze sources of variations of machines, materials, methods, and manpower from the beginning to end of a manufacturing or assembly process. ... Initially developed by AIAG (Auto Industry Action Group) in 1993 with input from the Big ...

62. Location: Greater Milwaukee USA. That is an old school diagram that General Motors required from suppliers back in the 80s. It was a few years before AIAG standardized the Control Plan format, so this was a combined process flow and control plan. This was before you could do this easily on a computer.

This encompasses alternate process flows and movement of product to and from external operations. Note 1: Within the process flow diagram, there shall be sufficient detail of the production process steps and sequence. Note 2: Process flow diagrams for families of similar parts are acceptable if the new

5.Process Flow Diagrams R R S * R 6.Process FMEA R R S * R 7.Control Plan R R S * R 8.Measurement System Analysis studies R R S * R 9.Dimensional Results R S S * R 10.Material, Performance Test Results R S S * R 11.Initial Process Studies R R S * R 12.Qualified Laboratory Documentation R S S * R 13.Appearance Approval Report (AAR), if ...

0 Response to "38 aiag process flow diagram"

Post a Comment