41 plate heat exchanger piping diagram

Boiler Pressure - Free Heating Advice Plate heat exchangers are secondary heat exchangers. Non-combi system boilers do not have secondary heat exchangers but nearly all combi boilers do. This fault, that causes continuously high pressure, is an internal leak in the secondary heat exchanger (plate heat exchanger). This is a heat exchanger in the boiler which has system water ... Types of Heat Exchanger: Parts, Working, Advantages, Uses ... Closed-loop liquid cooling is defined as a cooling system that uses liquid as a coolant and uses a heat exchanger to remove heat from the coolant. The most commonly used coolants are water, deionized water, disrupted glycol, and water solutions. In a liquid cooling loop, the coolant is pumped through a cold plate that is in contact with a heated integrated circuit.

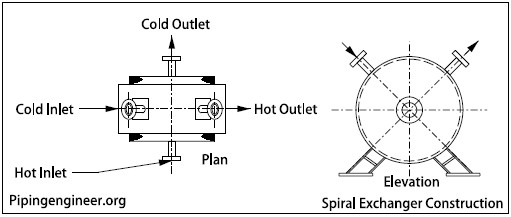

Heat Exchanger | Heat Transfer and Fluid Flow | Types ... Plate and frame heat exchanger; Spiral heat exchanger; Pipe coil exchanger; Air-cooled heat exchangers; 1.) Double-pipe heat exchanger:-A double-pipe exchanger has a pipe inside a pipe. The outside pipe provides the shell. And the inner pipe provides the tube. The warm and cool fluids can run parallel flow or counter current, because it is more ...

Plate heat exchanger piping diagram

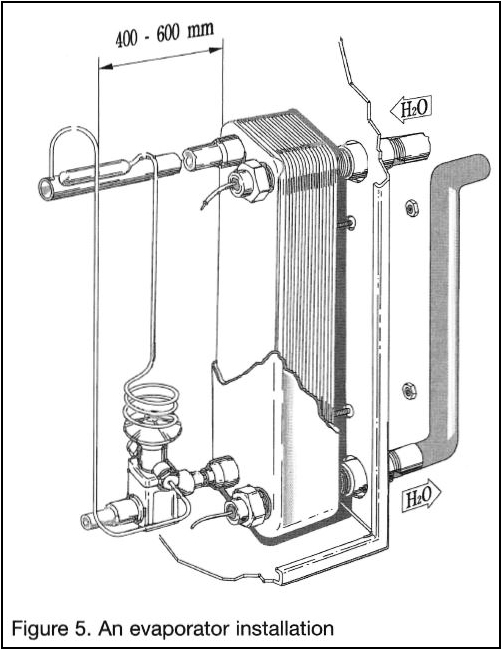

Startup characteristics of an ammonia loop heat pipe with ... Flat-plate loop heat pipe (FLHP) is a passive two-phase heat transfer device. Comparing with traditional LHP with a cylindrical evaporator, it can be directly connected to a flat heat source without the employment of a saddle, which can effectively reduce the system thermal resistance and enhance the temperature uniformity. In this work, a stainless steel-ammonia FLHP was developed, and ... Optimization of energy systems using the ... - Springer Three case studies including Rankine cycle, plate fin heat exchanger, and double pipe heat exchanger are discussed and optimized to show the benefits of this method. Introduction Usually, after designing a system, equipment or a plant is optimized by considering the objective function and selecting some design parameters. A. Answer all questions (2X5=10) 1. Discuss the plate heat ... A 30% glycol solution (rho = 67.2 lbm/ft^3, v = 6.28 times 10^-5 ft^2/sec) flows out of a centrifugal chiller at 285 gpm. The glycol solution flows through 50-ft-long of 2-in.-I.D. steel pipe before reaching a plate heat exchanger. The pipeline...

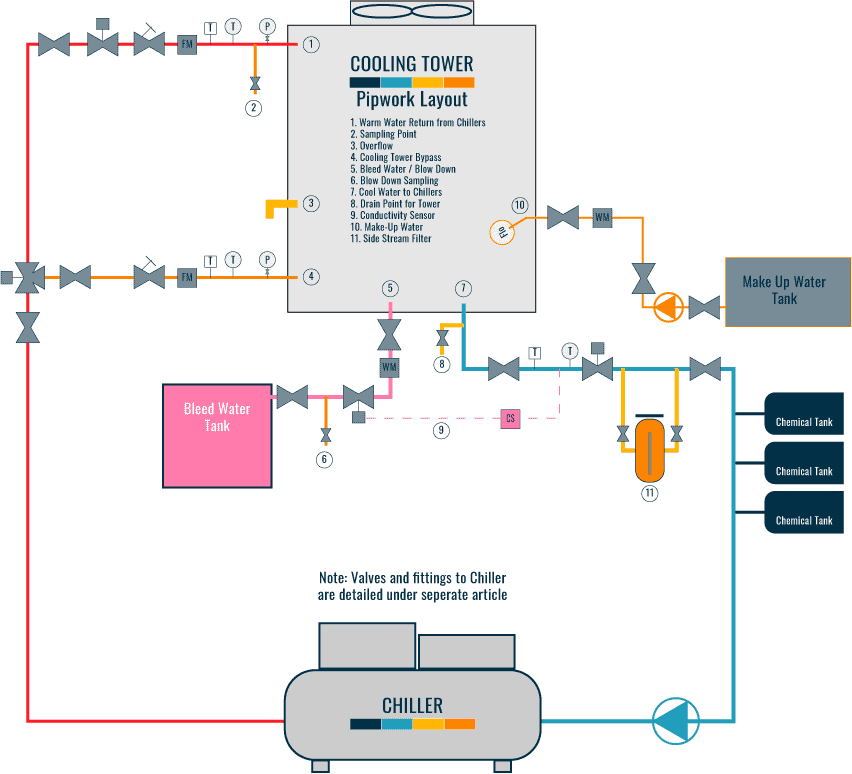

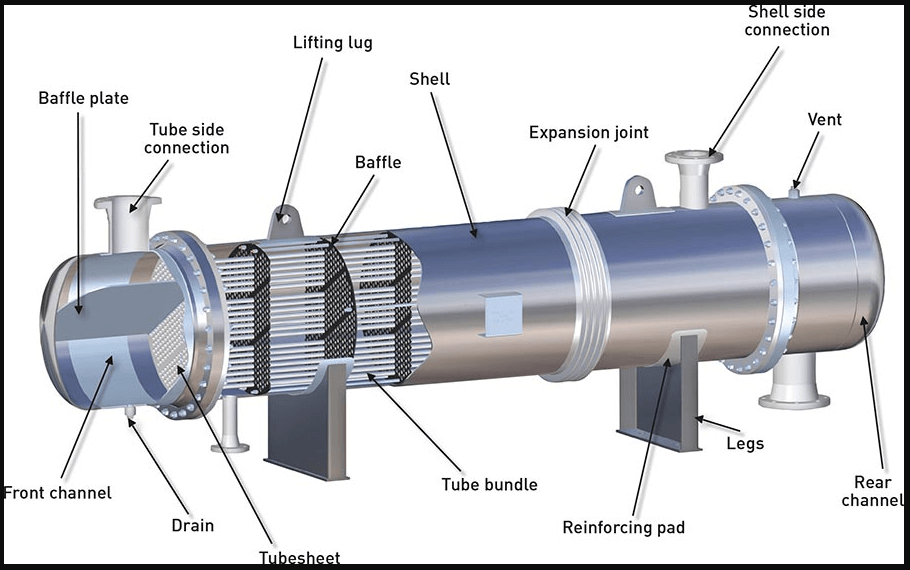

Plate heat exchanger piping diagram. › 2019 › 05Shell & tube heat exchanger diagram - EnggCyclopedia Apart from the internal structure, another important diagram for heat exchanger design, is the piping & instrumentation diagram or P&ID for heat exchanger. Following diagram is a typical P&ID arrangement for a shell & tube heat exchanger. This post explains the guidelines for creating a detailed P&ID diagram for a shell and tube exchanger. Pool & Spa, Residential and Commercial Hydronic ... Raypak Pool & Spa, Residential and Commercial Hydronic Products - en.wikipedia.org › wiki › Piping_and_instrumentationPiping and instrumentation diagram - Wikipedia Piping and Instrumentation Diagram manual drawing template (1980s) Symbol Key: A – Vessel dished end B – Motor driven pump or compressor and baseplate C – Valves D – Valve diaphragm actuator E – Shell and tube heat exchanger. F – Flexible hose, bellows G – Ejector. H – Machine driven pump or other device I – Reducers See also Heat Exchanger Software | Engineering Software and Tools All our heat exchanger software come with a free physical properties estimation software. Version v3.1.0.2. Double Pipe Heat Exchanger Design (DHex) Version: 1.0.0.3 New Software. Vertical Thermosiphon Design (VTD) Version: v2.1.0.1. Air Cooled Heat Exchanger Design (ACHex) Version: v1.1.0.1.

› publication › 308464270_Heat(PDF) Heat Exchanger Types and Classifications A heat exchanger is a heat transfer device that exchanges heat between two or more process fluids. Heat exchangers have widespread industrial and domestic applications. HVAC Plan Symbols and Their Meanings - EdrawMax - Edrawsoft HVAC (heating, ventilation, and air conditioning) plans refer to the drawings made by specialized engineers that include all the details needed to create, set up, and maintain the heating and cooling system in a building.. The HVAC plans are quite important and are developed once the building's floor plans have been completed. The engineers use their expertise to develop the most effective and ... Counter Flow Heat Exchangers and its Working ... - Linquip Counter Flow Heat Exchangers are called the exchangers, which have the opposite fluid direction for the flows and are categorized based on the flow arrangement. Plate, shell and tube, double-pipe, one phase, and multi-phase can be counter flow exchanger. ⇒ View a List of Heat Exchanger for Sale and Their Suppliers ⇐ 2022 Heat Exchanger Replacement Cost | Furnace or Boiler A heat exchanger for a boiler costs $100 to $300 on average, depending on the boiler type, size, and BTU rating. Most boilers need a brazed plate heat exchanger for a water-to-water heat transfer system. Modern condensing boilers have two heat exchangers that increase energy efficiency. Commercial / industrial heat exchanger prices

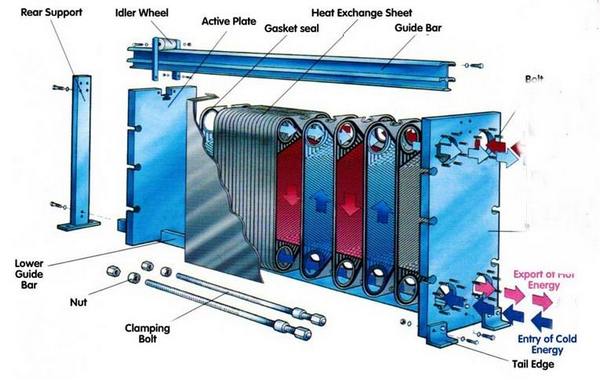

PETRONAS Technical Standard (PTS) - Research Support ... Heat Exchanger - Brazed Aluminium Plate-Fin Type: 12.21.05: Heat Exchanger - Printed Circuit (PCHE) Type: 12.21.08: Heat Exchanger - Plate And Shell (PSHE) Type: ... Identification of Instrumentation Tags on Piping and Instrumentation Diagram (P&ID), DCS and MMS: 14.00.04: Instrument Project Engineering Procedures: 14.00.05: Instrument ... Steady-state operating characteristics analysis of loop ... Fig. 1(a) shows the typical diagram of a flat-plate LHP system. The system is mainly composed with an evaporator, a compensation chamber, a condenser, a vapor and liquid line. The flat-plate LHP is more suitable for fitting with electronic heat dissipation components due to its flat evaporator design, which can perform better on heat transfer . Plate Heat Exchanger: Types and Working Principles | Linquip A plate heat exchanger is a type of heat exchanger using metal plates to transfer heat between two fluids never encountering each other due to being separated by the heat exchanger. This article is about the design, working principle, and an introduction to different types of Plate Heat Exchanger. Heat Exchangers with Temperature Pinch - Heat Transfer ... Does a Plate Heat Exchanger suitable. 3. Are Plate Heat Exchangers suitable for Temperature Meet, Cross and Pinch. RE: Heat Exchangers with Temperature Pinch ... the piping can and should be arranged to provide pure countercurrent flow, ... I've misinterpreted the application of diagram f and h in Fig 11-4 in Perry 7th edn. The schematic ...

Lifting Lug Design with example - What Is Piping Lifting Lug Design with example. Written by Anup Kumar Dey in Mechanical, Piping Interface, Piping Stress Analysis. A Lifting lug is a plate with a hole in it. As the term specifies, lifting lugs are used for lifting. The hole is sized to fit a clevis pin. Using lifting lugs combined with the clevis pins, loads are transferred from one ...

Types of Heat Exchangers Used on Ship - Marine Insight 3) Plate Fin Heat Exchanger. Plate and fin type heat exchanger is constructed similar to a plate-type exchanger but also contains fins to increase the efficiency of the system. Aluminium alloy is used as it gives higher heat transfer efficiency and lowers the weight of the unit.

Process Flow Diagram Symbols and Their Usage - Edraw It can be used for both heating and cooling purposes. The main use or purpose of this device is the transfer of heat from one medium to another, and it is also used for cooling purposes. TYPES: Shell and tube heat exchangers. Double pipe heat exchangers. Condensers, evaporators, and boilers. Plate heat exchangers.

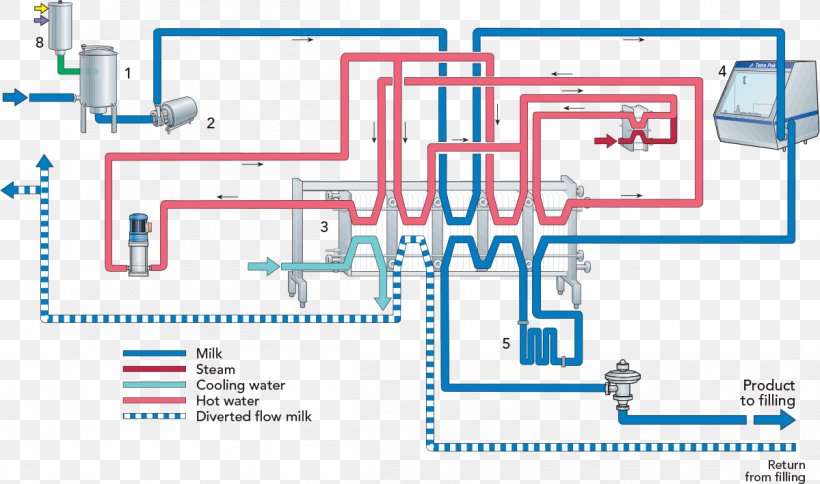

How Do Heat Exchangers Work - A 101 Guide Heat exchangers help control fluid temperatures in food, beverage, and pharmaceutical processing for pasteurization, sterilization, clean-in-place and other hygienic operations. In this post, we discuss how three types of heat exchangers work: plate and frame, shell and tube, and scraped surface. The purpose of heat exchangers is to transfer heat between two or more fluids to regulate ...

4 Types of Heat Exchangers | Zwirner Equipment 4. Plate Heat Exchangers: While all of the types of heat exchangers discussed so far have a similar design, the plate heat exchanger is the exception. Metal plates are used to transfer heat between two fluids. The plate is a metal shell, with spaces inside each plate that act as hallways for fluids to travel through.

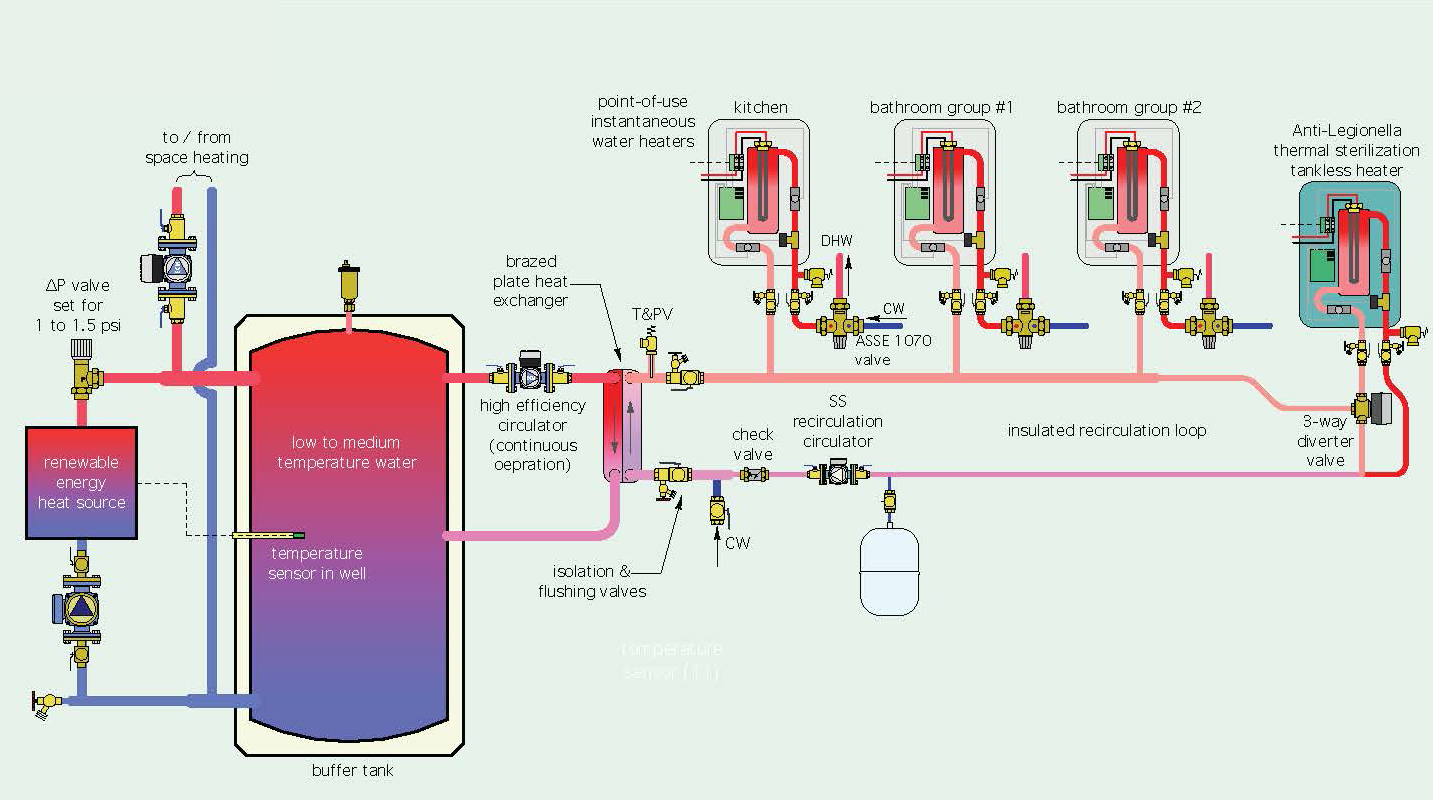

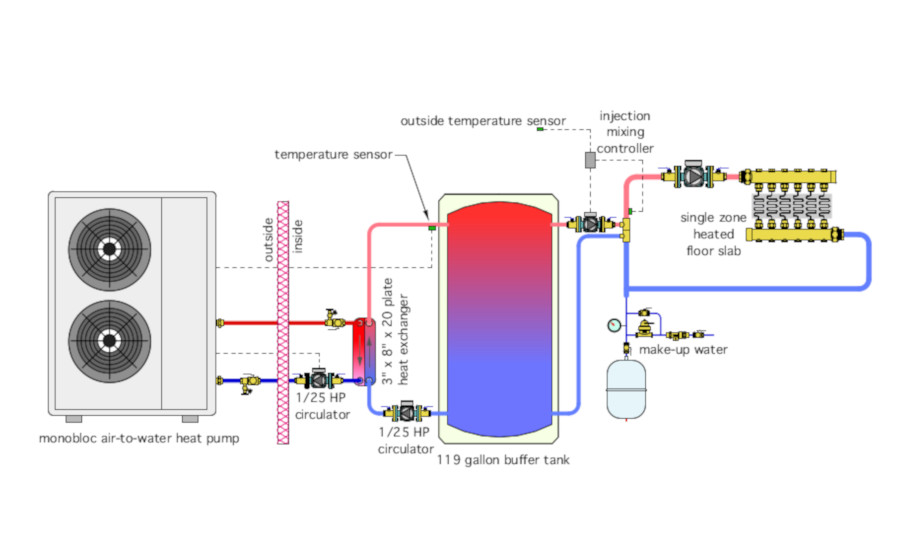

HYDRONIC HEATING: Schematics & Video On How to Use a Tank ... This is why the best system designs include a heat exchanger to transfer heat from the domestic hot water to the space heating water, without the two kinds of water mixing. Plate-style exchangers work best in this application, though they do need to be descaled every 6 months to 2 years by running vinegar through the exchanger with a transfer pump.

How Heat Recovery Systems Work | All You Need To Know And depending on the arrangement of the heat pipe, the fluid or gas is usually transported from one side of the pipe to the other through pressure or gravity. Fixed Plate Heat Exchangers After being developed for 40 years, fixed plate heat exchangers have emerged as the most commonly used heat exchangers in the market today.

chemicalprocessengineering.com › heat-exchangersSelection of Shell & Tube Heat Exchangers | TEMA Types ... The tubesheet is welded to the shell and the heads are bolted to the tubesheet. On the NEN heat exchanger, the shell and the head is welded to the tubesheet. Typically, a cover plate design is provided to facilitate tube cleaning. This TEMA category, especially the NEN, is the lowest cost TEMA design per square foot of heat transfer surface ...

Tipo Heat Exchangers and Cooling Towers Manufacturers ... Shell and Tube Heat Exchangers offer large surface area in combination with efficient heat transfer and compactness. These are widely used in industries for various duties like cooling, heating, condensation, evaporation etc. Tipo Heat Exchangers are the pioneers in the field of glass shell and t...

What Is a Bypass Valve on a Swimming Pool ... - Dengarden A pool heater contains copper elements: more specifically, the "heat exchanger." This is the point where the water is actually heated and then returned back to the pool. Although in recent years there has been an increase in the production of titanium heat exchangers, most existing pool heaters and heat pumps still have a copper exchanger.

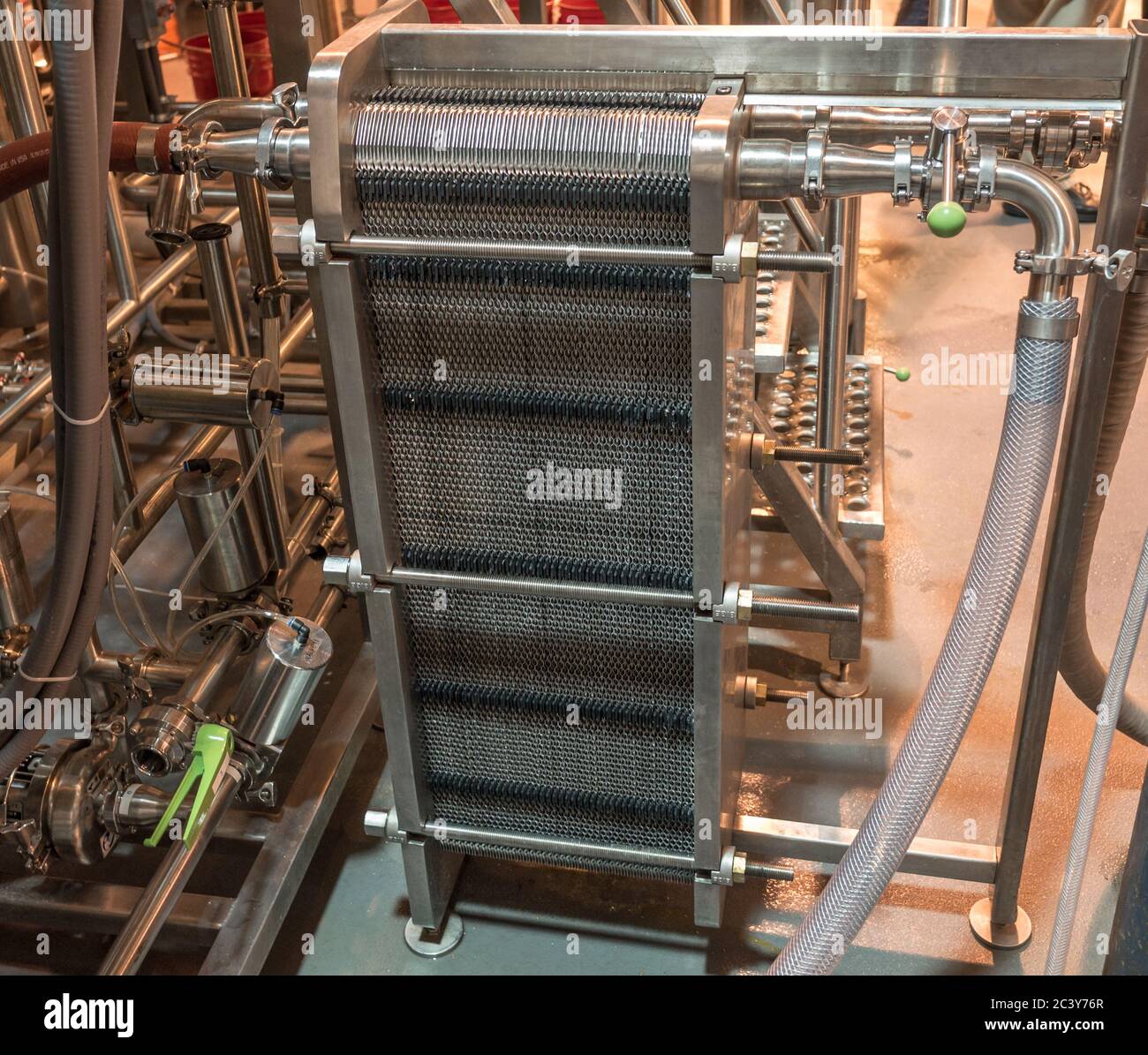

Plate Heat Exchanger (For Dummies) | Rasmussen Mechanical Provides high value for your overall heat transfer. A flat plate heat exchanger typically has a U value much higher than a shell and tube heat exchanger or a spiral heat exchanger. It creates a compact design. Plate heat exchangers have the same thermal capacity as a shell and tube heat exchanger as much as five times its size.

A Cryogenic Test Rig for Dynamically Operated Plate‐Fin ... The main heat exchanger, typically an aluminum plate-fin heat exchanger (PFHE), has been identified as one of the critical key components when it comes to lifetime of a flexibly operated ASU 5. While the number of load changes, startup and shutdown events during the lifetime of an ASU is comparably low (approx. 100) for steady-state operation ...

SWEP brazed plate heat exchangers - SWEP Brazed plate heat exchangers are one of the most efficient ways to transfer heat. They are designed to provide unparalleled performance with the lowest life-cycle cost. Read more about BPHEs Latest news. Enhancement of the All-Stainless range with B222 large-size model February 25, 2022 ...

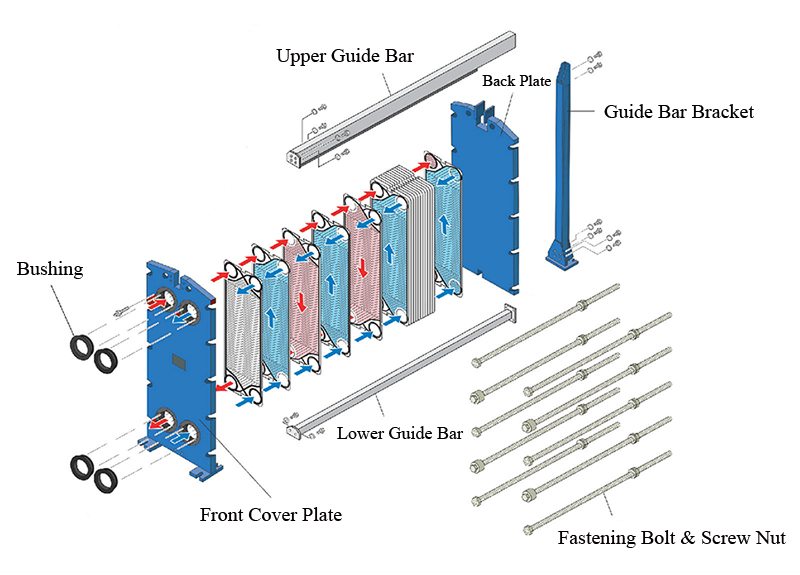

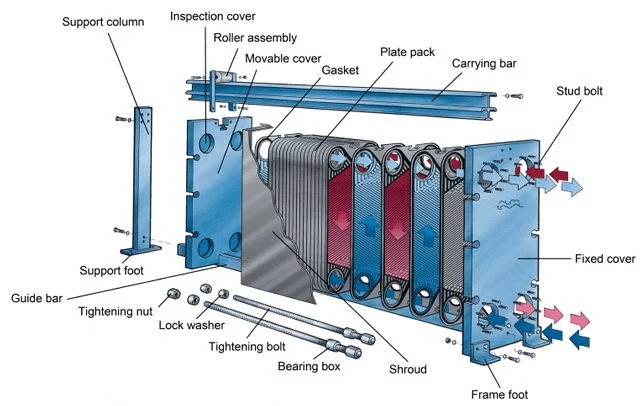

en.wikipedia.org › wiki › Heat_exchangerHeat exchanger - Wikipedia 3. Plate Heat Exchanger A plate heat exchanger contains an amount of thin shaped heat transfer plates bundled together. The gasket arrangement of each pair of plates provides two separate channel system. Each pair of plates form a channel where the fluid can flow through. The pairs are attached by welding and bolting methods.

A Visual Guide to a High-Efficiency Condensing Furnaces Secondary Condensing Heat Exchanger . In condensing furnaces, there is a secondary heat exchanger made up of small tubes that receive the exhaust gases once they have gone through the primary heat exchanger. Here, more heat is extracted, resulting in the gases that are cooled to the point that they condense into water and carbon dioxide.

Chapter 6. Heat Transfer from Extended Surfaces (FINS ... Determine heat flow rate from 1 m length of pipe. Compare the heat flow with fins to that without the fins. A hot plate (1 m x 1 m), at 150°C is to be cooled by attaching on its surface, 10,000 number of cylindrical, pin fins of each, 3 mm diameter and 3 cm long. ... heat transfer rate from the plate, if there were no fins;

› 047 › 102687954-Heat-ExchangerDesign and Analysis of Heat Exchanger - 123seminarsonly.com The ultimate aim of this report is to design an Air Cooled Heat Exchanger, preferably of shell and tube type, that can be used to transfer the heat energy generated in the windings of 3-phase Induction motor working at 800 rpm (Assumed). Following figure details the boundary conditions for the heat exchanger. Specifications:

How do heat exchangers work? - Explain that Stuff Plate/fin heat exchangers have lots of thin metal plates or fins with a large surface area (because that exchanges more heat more quickly); heat exchangers in gas furnaces (gas boilers) work this way. Artwork: A simple example of a plate/fin heat exchanger. This is a cross-flow design with the two fluids flowing past one another at right angles.

A. Answer all questions (2X5=10) 1. Discuss the plate heat ... A 30% glycol solution (rho = 67.2 lbm/ft^3, v = 6.28 times 10^-5 ft^2/sec) flows out of a centrifugal chiller at 285 gpm. The glycol solution flows through 50-ft-long of 2-in.-I.D. steel pipe before reaching a plate heat exchanger. The pipeline...

Optimization of energy systems using the ... - Springer Three case studies including Rankine cycle, plate fin heat exchanger, and double pipe heat exchanger are discussed and optimized to show the benefits of this method. Introduction Usually, after designing a system, equipment or a plant is optimized by considering the objective function and selecting some design parameters.

Startup characteristics of an ammonia loop heat pipe with ... Flat-plate loop heat pipe (FLHP) is a passive two-phase heat transfer device. Comparing with traditional LHP with a cylindrical evaporator, it can be directly connected to a flat heat source without the employment of a saddle, which can effectively reduce the system thermal resistance and enhance the temperature uniformity. In this work, a stainless steel-ammonia FLHP was developed, and ...

![PDF] The use of plate heat exchangers to improve energy ...](https://d3i71xaburhd42.cloudfront.net/128d447903e83d3484213f829898eed052cb32db/6-Figure4-1.png)

![PDF] The characteristics of condensation in brazed plate heat ...](https://d3i71xaburhd42.cloudfront.net/b37e14ddd50437f3b2f0acc8f10822fa3433dd72/2-Figure1-1.png)

0 Response to "41 plate heat exchanger piping diagram"

Post a Comment