38 block and tackle rigging diagram

Block & Tackle Rigging - Snatch Blocks Mike Parnell Oct 29, 2010 Block and tackle rigging and skidding loads via winch and snatch blocks are tried and true rigging systems which are still actively used in underground mining, ship repair, power utility work, machinery installation/removal, logging and millwright jobs in many industries.

Rigging Methods. A tackle may be. "Rove to advantage" - where the pull on the rope is in the same direction as that in which the load is to be moved. The hauling part is pulled from the moving block. "Rove to disadvantage" - where the pull on the rope is in the opposite direction to that in which the load is to be moved.

All you need to do is select any software and follow the steps of drawing block and tackle rigging diagram. Step 01 Download and open EdrawMax in your pc. Step 02 Select an empty canvas where you can make your diagram. Or, nagivate to [Science and Education] > [Mechanics], find and open a template. Step 03

Block and tackle rigging diagram

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features Press Copyright Contact us Creators ...

Block and tackle rigging diagram new sail plan is a part of 17 best of block and tackle rigging diagram pictures gallery. Incidentally youll often hear the rope or tackle called the fall block and tack or block and fall. The traditional block and tackle uses rotating pulleys but a sturdy pivot point such as rock climbers carabiners.

Garnet Tackle •The garnet tackle is also part of the standing rigging, although it could be considered running rigging also. Check with the proper authority to determine the correct tackle to use, since it varied by nationality and period. Used to hoist boats, guns, etc.

Block and tackle rigging diagram.

Jun 4, 2016 - Reeving blocks to set up a double pulley system requires a little thought. A double pulley system, also known as a "block and tackle," consists of the pulleys, or blocks, and the tackle, the ropes riven through the blocks. You must decide if you will use a double pulley system with one sheave--the roller in a ...

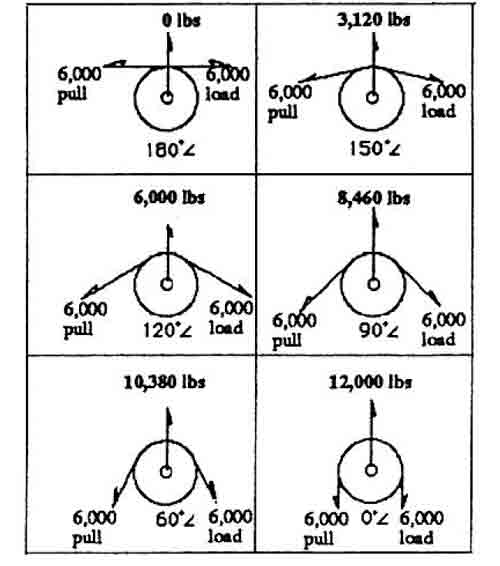

Lower Block (LBS.) Working Load Limit for Crosby Blocks indicates the maximum load that should be exerted on the block and its connecting fitting. A single sheave block used to change load line direction can be subjected to total loads greatly different from the weight being lifted or pulled.

Main Boom Rigging. November 24, 2017. Day 602. With the masts rigged, attention shifts to rigging the booms and gaffs. Booms are like horizontal masts located low on the ship near the deck. Gaffs are higher up. The Bluenose has three booms. The jumbo jib boom is located near the bow, forward of the fore mast.

Reeving blocks to set up a double pulley system requires a little thought. A double pulley system, also known as a "block and tackle," consists of the pulleys, or blocks, and the tackle, the ropes riven through the blocks. You must decide if you will use a double pulley system with one sheave--the roller in a ...

Perhaps the rigging diagram has just omitted the tackle for the other pendant for clarity. It is often the case that rigging plans only show one side and you just assume the duplication on the other side. The function of the truss, or parrels was to confine the yard in to the mast.

rope or tackle called the fall, block and tack, or block and fall. In the Navy you'll rig a block and tackle to make some of your work easier. Learn the names of the parts of a block. Figure 2-1 will give you a good start on this. Look at the single block and see some of the ways you can use it. If you lash a single block to a fixed object-an

Rigging program. It requires persons who perform rigging or operate hoisting equipment to be trained to ensure that the personnel are competent to perform the operation. The qualification is for a period the three years. The training requires a written exam and practical demonstration. The requirements for operator training and

Place canvas on the shroud about half-way up to avoid chafe, and tail the upper block of a rigging luff (gun tackle purchase) over it. Hook the lower block of the luff to a strap on the end of the laniard, and lead the fall of the luff up to the pendant tackles as in Fig. 315. The luff tails should be dogged on long so as not to nip the shroud.

Block and tackle rigging diagram. Reeving blocks to set up a double pulley system requires a little thought. Secure pulley number one to the anchor point. While the device is quite simple the rope must be properly threaded through the device in order for it to work properly.

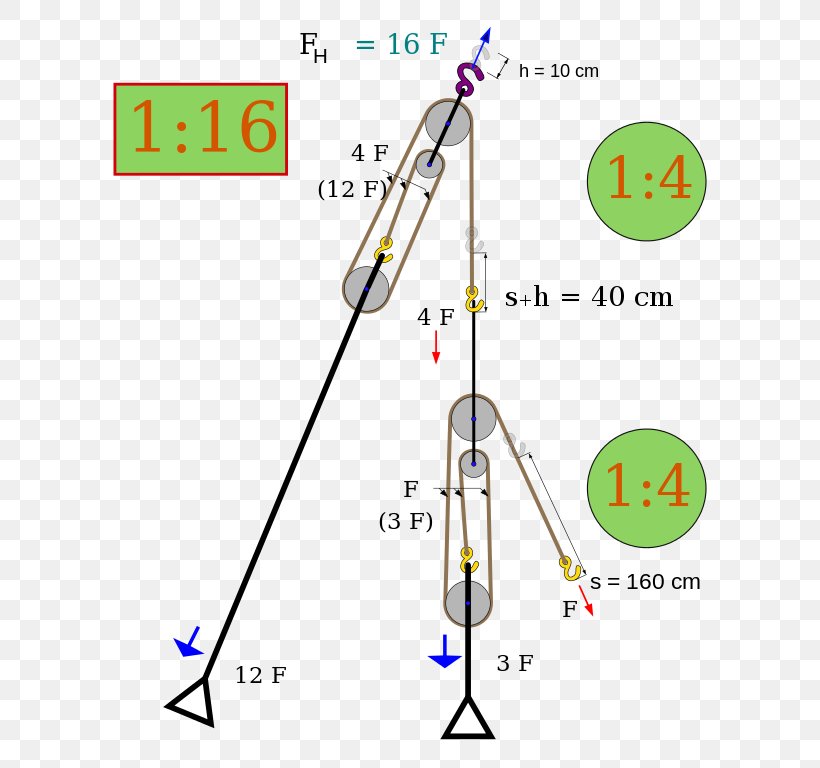

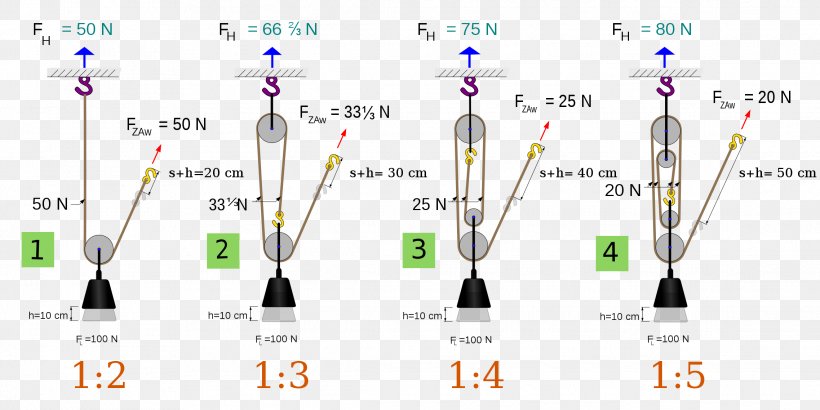

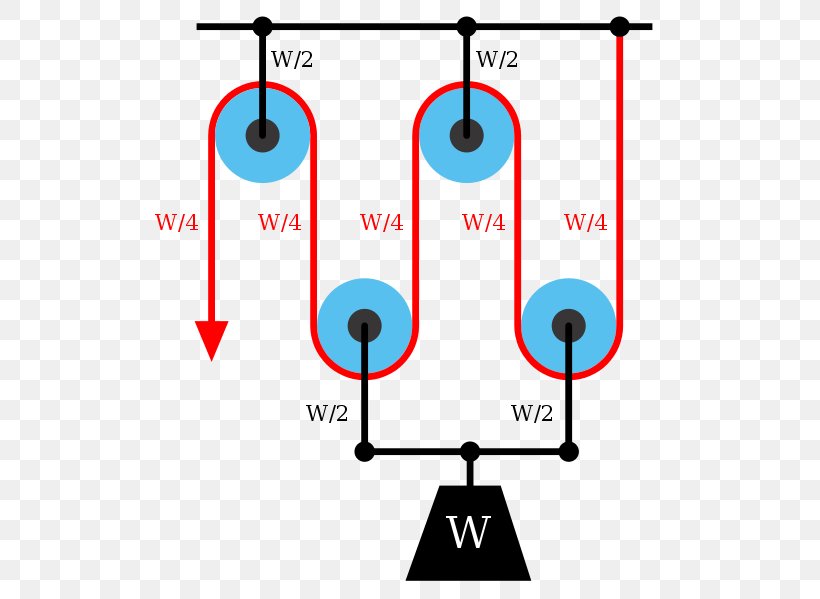

The Block & Tackle system trades a smaller force on the line, that is running through the system, for a longer distance of line travel through the system to get the same job done. Let's pretend that friction does not exist, and only consider the static (non-moving) state of the system. ... If we rig a 3:1 system, the diagram looks like this:

ers the types of rigging and the application of fiber rope, wire rope, and chains used in various combinations to raise or move heavy loads. It includes basic instructions on knots, hitches, splices, lashing, and tackle systems. Safety precautions and requirements for the

ging heavy loads with tackle block assem - blies. • Failure to design and use tackle block systems properly may cause a load to slip or fall - the result could be serious injury or death. • A tackle block system should be rigged by a qual-ified person as defined by ANSI/ASME B.30. • Instruct workers to keep hands and body away

Secure the fixed or stationary block to the rear anchor. The fall line should come out of the running block to give greater MA to the tackle system. Stretch the tackle system to the base of the gin pole before erecting it to pre-vent the tackle blocks from chocking. Haul in on the fall line of the tackle system, keeping a slight tension on the

All blocks are rigged from left to right and downward. Estimating the IMA Calculate the IMA of a block and tackle set by reducing the total number of pulleys filled with rope by one. The double-pulley block and tackle rigged in the above steps will have an IMA of three. G.K. Bayne

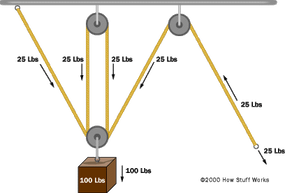

A block is a set of pulleys or sheaves mounted on a single frame. An assembly of blocks with a rope threaded through the pulleys is called tackle. The process of threading ropes or cables through blocks is called "reeving", and a threaded block and tackle is said to have been "rove".A block and tackle system amplifies the tension force in the rope to lift heavy loads.

Block Reeving. Straight laced reeving is a basic method of placing the rope through a set of blocks. The end of the rope is fed through the outside sheave of the upper block to the outside sheave of the lower (traveling) block. This continues to the last sheave.

Block and Tackle Rigging Diagram. Get Started! You Will Love This Easy-To-Use Diagram Software. EdrawMax is an advanced all-in-one diagramming tool for creating professional flowcharts, org charts, mind maps, network diagrams, UML diagrams, floor plans, electrical diagrams, science illustrations, and more. Just try it, you will love it!

In this video, we take a look at some popular rigging blocks. Find out what makes them different and which ones best suit your needs. Check out the epic prod...

rigging components, such as slings, shackles, eye bolts, and turnbuckles. The "Lifting Safety" Subject Area, found in the Brookhaven National Laboratory (BNL) Standards-Based Management System (SBMS), governs all lifts conducted at BNL. The Subject Area contains guidance that must be used in order to plan and perform a lift safely.

Block and tackle rigging diagram. In this diagram the pulley attached to the weight actually consists of two separate pulleys on the same shaft as shown on the right. These systems distribute weight across the pulleys and allow a person to lift much heavier loads than possible by hand.

The feature is especially valuable in crane rental operations, or conditions in which the line parts of a block must be changed frequently. The Reeving of Tackle Blocks In reeving of tackle blocks, there are many methods. The method discussed below is referred to as "Right Angle" reeving. Please consult your rigging manual for other methods ...

A simple pulley system. If you have ever looked at the end of a crane, or if you have ever used an engine hoist or a come-along, or if you have ever looked at the rigging on a sailboat, then you have seen a block and tackle at work. A block and tackle is an arrangement of rope and pulleys that allows you to trade force for distance.

To determine total load on block F: F = 500 lbs. x 1.41 = 705 lbs. (line pull) (Factor 90° angle) The Reeving of Tackle Blocks In reeving of tackle blocks, there are many methods. The method discussed below is referred to as "Right Angle" reeving. Please consult your rigging manual for other methods of reeving. RIGHT ANGLE REEVING

![Block and Tackle Rigging Diagram [+ Examples] | EdrawMax](https://images.edrawsoft.com/articles/what-is-block-and-tackle/block-and-tackle-in-use.png)

![Block and Tackle Rigging Diagram [+ Examples] | EdrawMax](https://images.edrawsoft.com/articles/what-is-block-and-tackle/the-whip-and-the-runner.gif)

0 Response to "38 block and tackle rigging diagram"

Post a Comment