40 steam boiler piping diagram

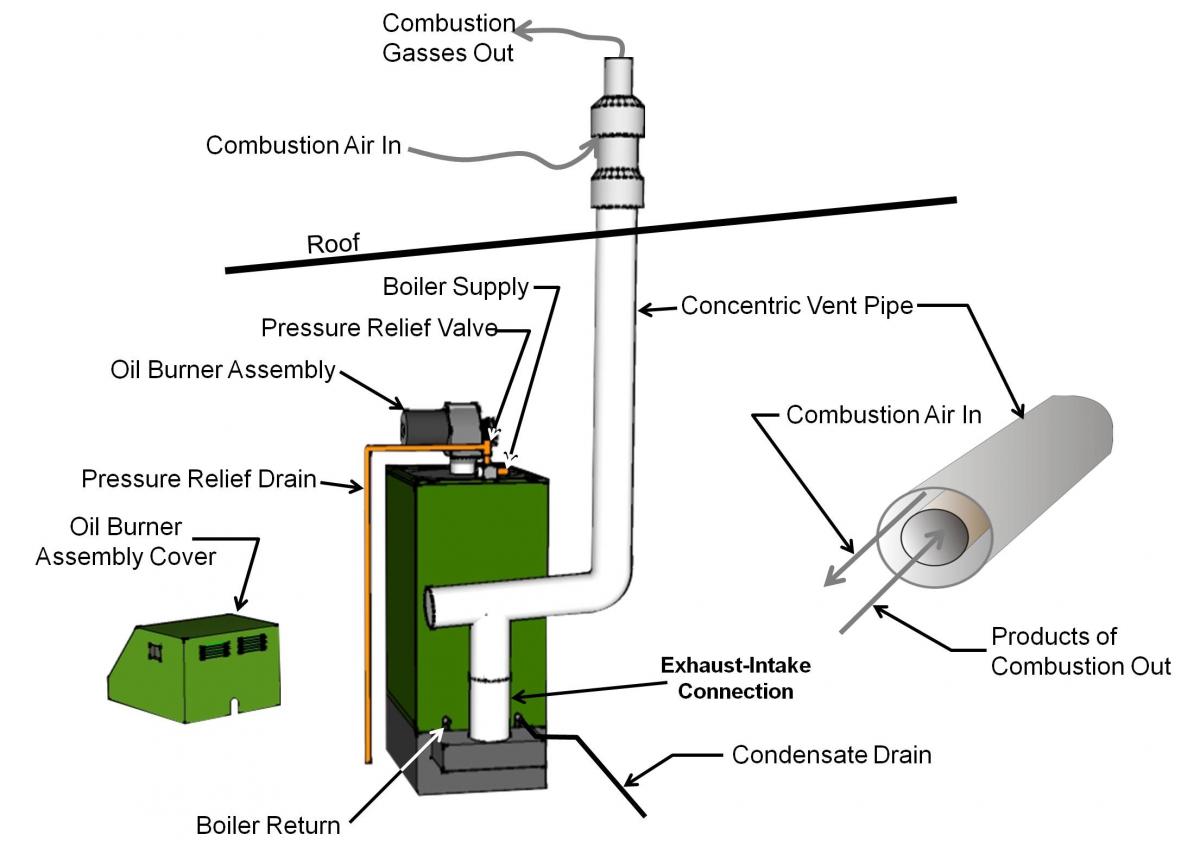

Process 2–3 Constant pressure heat addition in a boiler – Isobaric Heat Supply: The high-pressure liquid enters a boiler, where it is heated at constant pressure by an external heat source to become a dry saturated vapour (steam). The required energy input can easily be calculated graphically, using an enthalpy–entropy chart (Mollier diagram or h-s chart), or numerically, using steam tables. 1 Nov 2020 — VENT PIPE – ALL VERTICAL. NO HORIZONTAL SECTIONS. 1. PROJECT DESIGN AND FLOW DIAGRAM SHALL BE IN CONFORMANCE WITH SPECIFICATIONS. 2. SHOW VALVES ...1 page

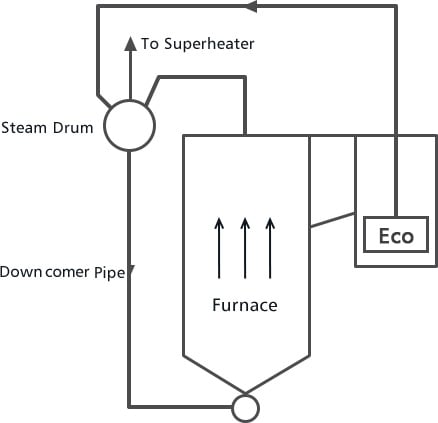

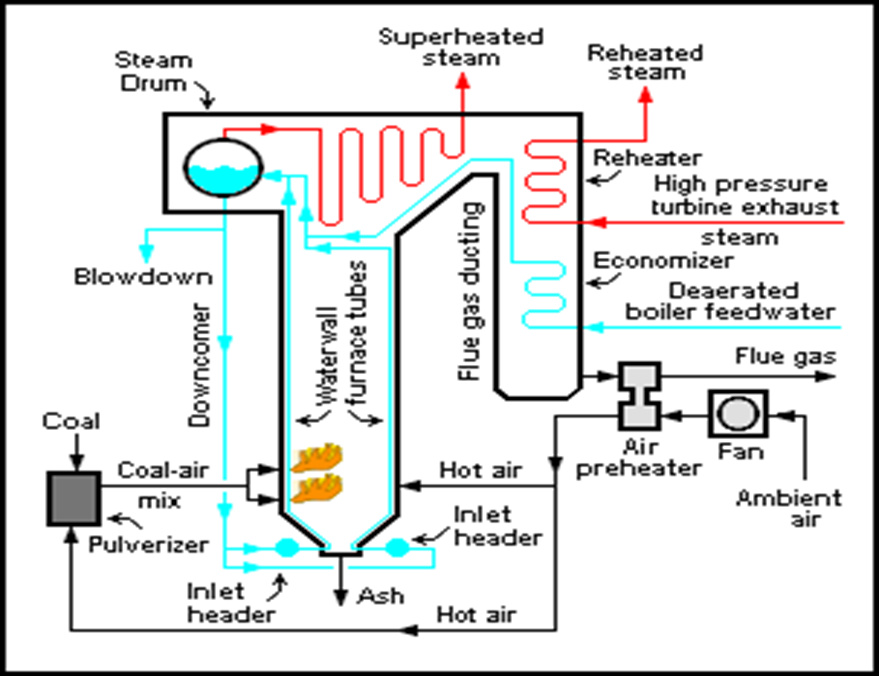

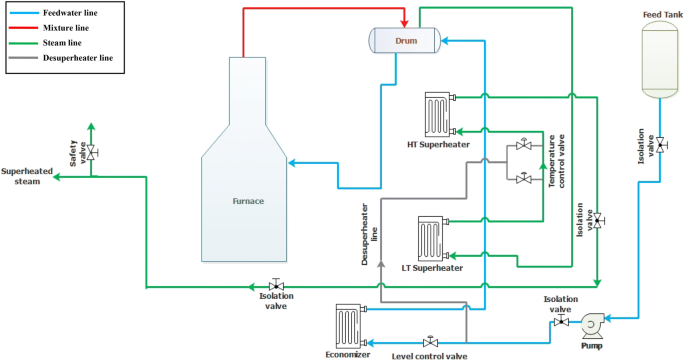

The steam piping is directed through the flue gas path in the boiler furnace, an area in which the temperature is typically between 1,300 and 1,600 degrees Celsius (2,372 and 2,912 degrees Fahrenheit). Some superheaters are radiant type, which as the name suggests, they absorb heat by radiation. Others are convection type, absorbing heat from a fluid. Some are a combination of the two types ...

Steam boiler piping diagram

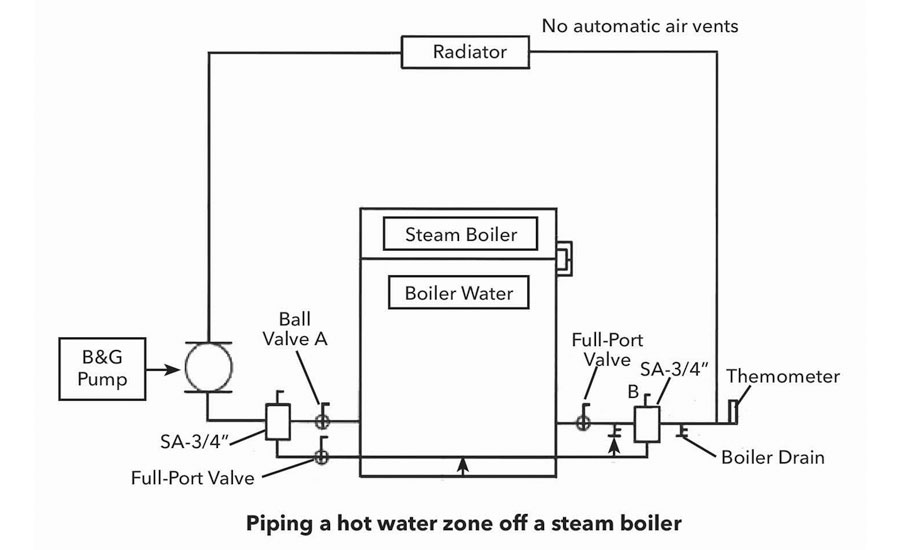

Hot Water Boiler Piping Zone Valves - Boiler piping zone valves are used for zoning hot water systems where multiple zones are needed.Hot water system zoning can also reduce energy cost because hot water heat zones which are not needed can be shut down thereby reducing boiler runtime to provide hot water heat for those specific zones.. Zoning a hot water boiler system can be done by using ... This boiler, gas piping and accessories must be installed, con- ... WIRING DIAGRAMS FOR STEAM BOILERS WITH VENT DAMPER. STEAM (PZ,PZT AND PPZT) BOILER WITH ...20 pages Piping Diagram GC-160 (Discontinued) GC-160 (Discontinued) Piping Diagrams for Model 160 Combi/Heat Only Boiler ... Specification for 28HE Series High …

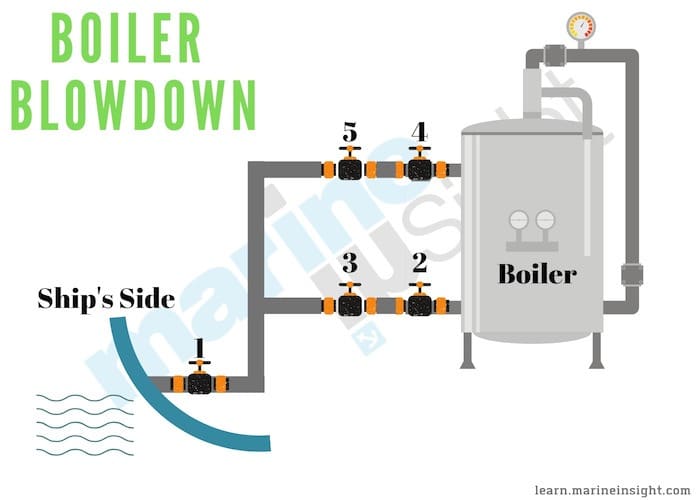

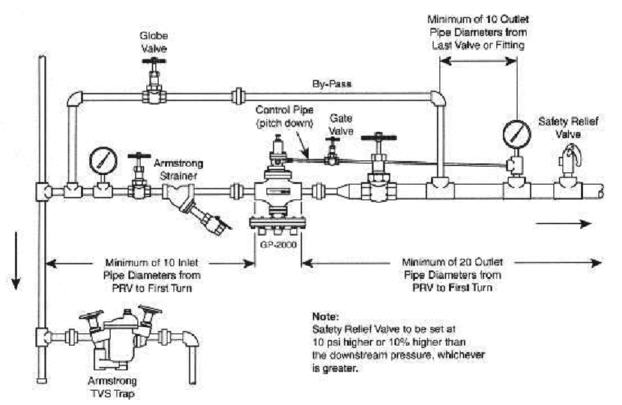

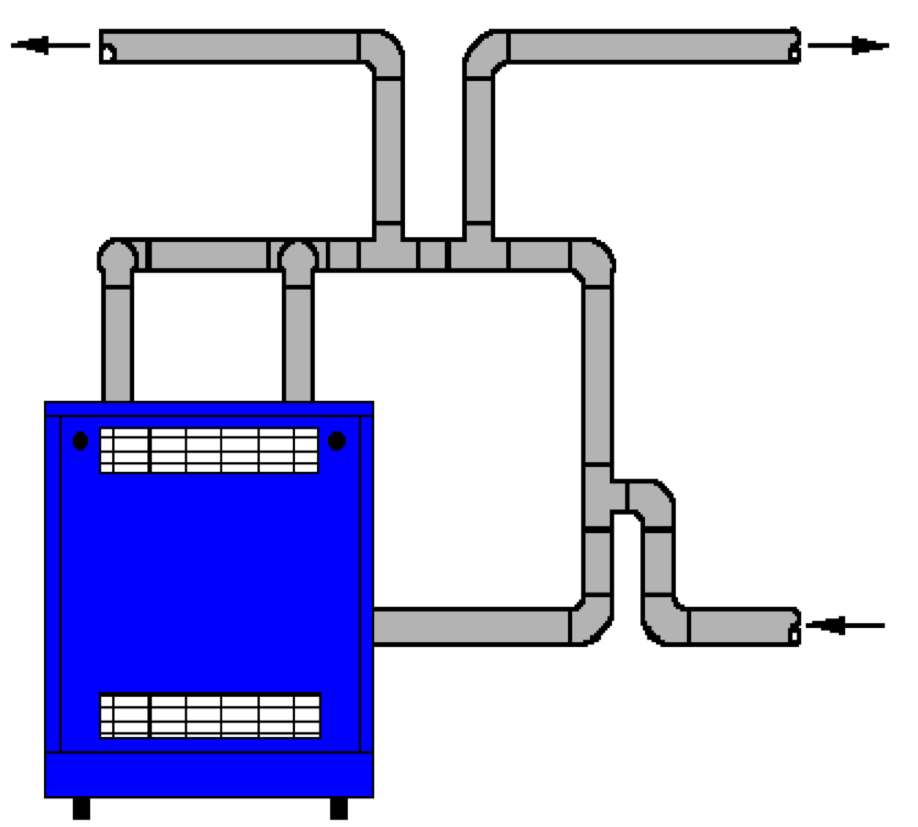

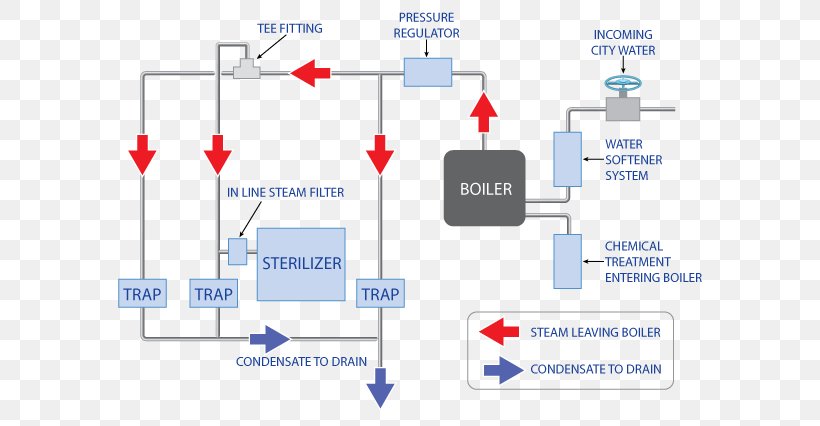

Steam boiler piping diagram. Steam Boiler Piping Diagram. Sharing. Published: February 20, 2018. Categories: Steam. Steam boiler piping: The right way to pipe takeoffs from a header. Steam Boiler – high or low pressure ... Surface blow down (TDS) control system for boiler – recommended ... Proper layout design & pipe sizing of mains.127 pages Steam Piping Best Practices Introduction. Just because it’s ‘been that way’ for a long time, don’t assume it’s right. In many cases steam systems were designed long before there was any concern about energy efficiency. Systems may have not been installed according to design because of some problem in the field – either something didn’t fit, got changed or an installer thought ... inches above the normal boiler water line. B. SYSTEM CHECKLIST. 1. The system piping must provide dry steam—wet steam causes water hammer, component damage ...

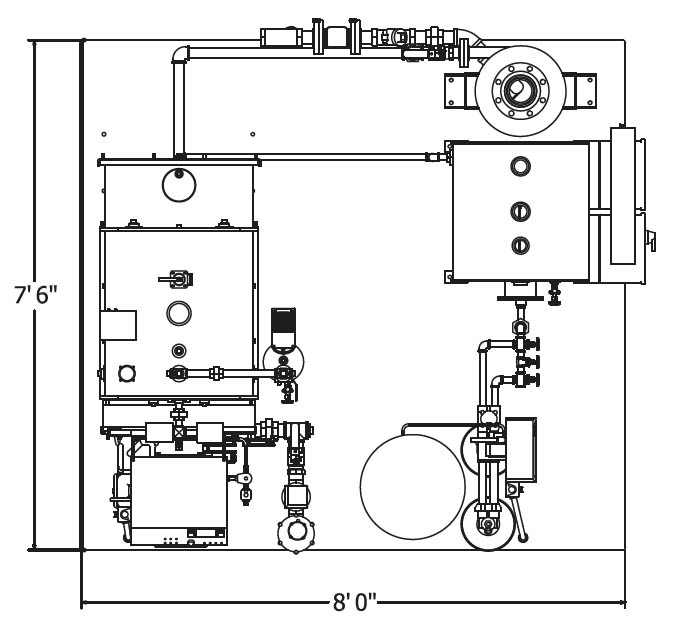

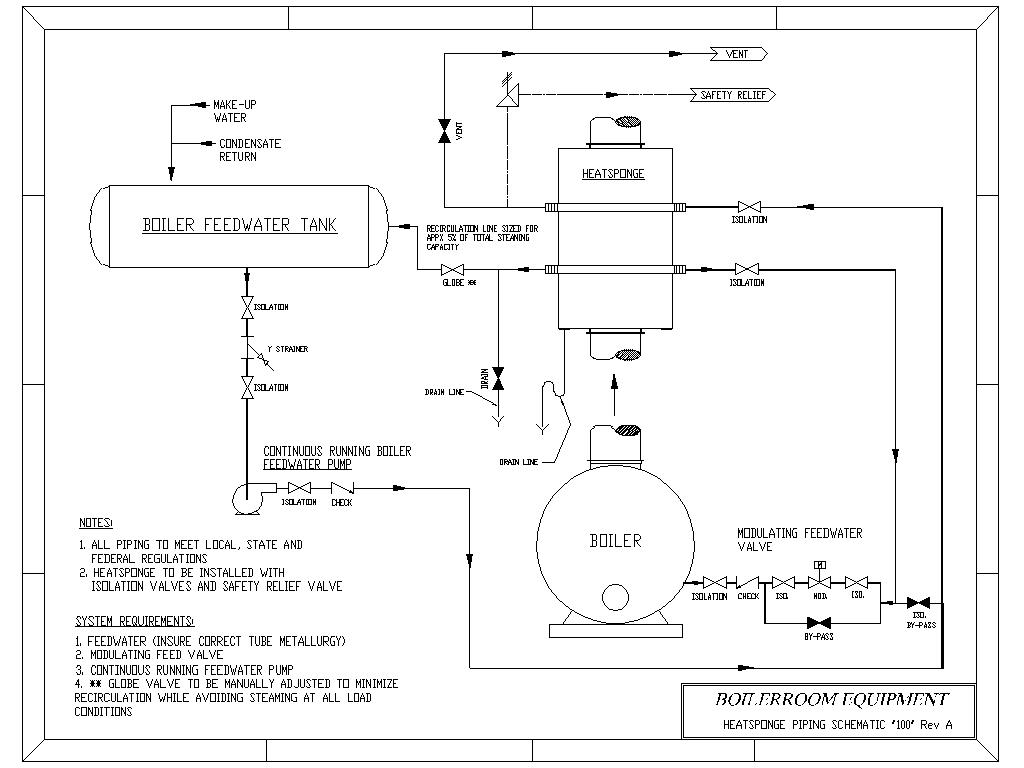

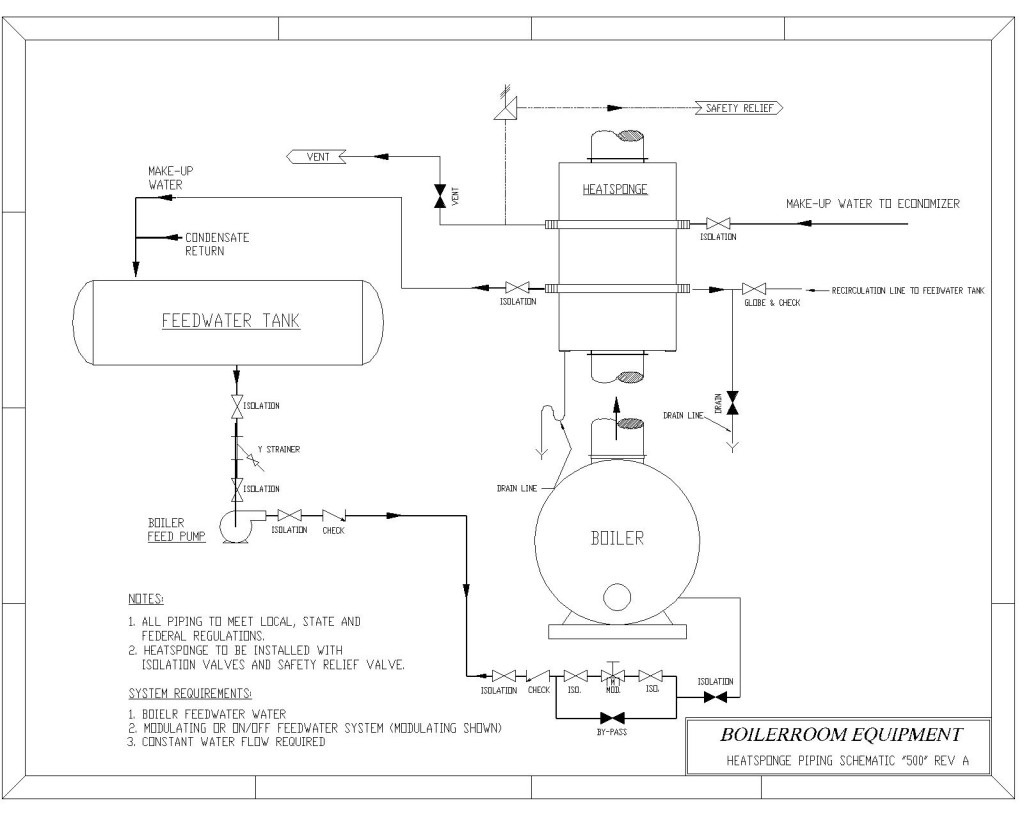

superheating the steam in the boiler and condensing it completely in the condenser. This cycle that results is the Rankine cycle, which is the ideal cycle for vapor power plants. The construct of power plant and T-s diagram is shown in Figures 2.2(a) and (b). (a) 2 q (b) Figure 2.2 : Rankine Cycle 1 4 3 2 T s 4 3 T 2 s Boiler Turbi ne Condenser 1 q out W turb,out 2 w pump,in q in Pump 3 4 3 1 ... The steam dryness fraction is used to quantify the amount of water within steam. Dry steam - all water molecules are in the gaseous state; Wet steam - a portion of the water molecules have lost their energy - latent heat - and condensed to tiny water droplets; To produce 100% dry steam in an boiler and keep the steam dry throughout the piping system is in general not possible. Steam & Boiler Fired Water Heaters; Unfired Steam Generators (USG) Plate Water Heaters (SPH & BPH) Electric Water Heaters & Boilers; Controllers. Cem-Trol II (Water Heater) Cem-Trol (Water Heater) Steam-Trol (USG) SSCM-2001 (USG) Stainless Steel Level Control (USG) RWD62U Controller (USG) RWX Controller (USG) T775 (Water Heater) RWX Controller ... Piping connections - All flanged piping connections should stand-off at least 150 mm to facilitate insulation. All screwed connections should stand-off by at least 20 mm. Lifting lugs - It is essential to fit lifting lugs to allow safe and easy installation. Feed tank piping Condensate return. As steam is generated, the water within the boiler evaporates and is replaced by pumping feedwater ...

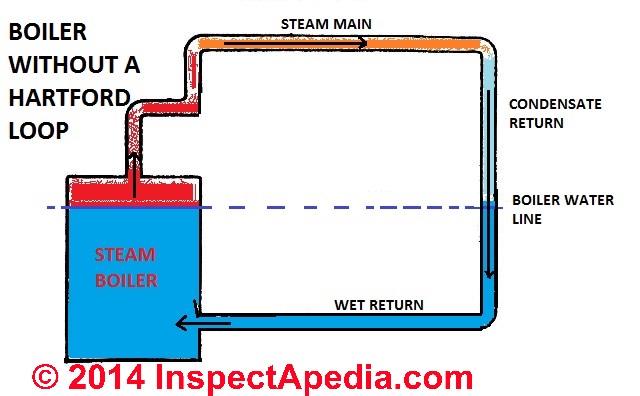

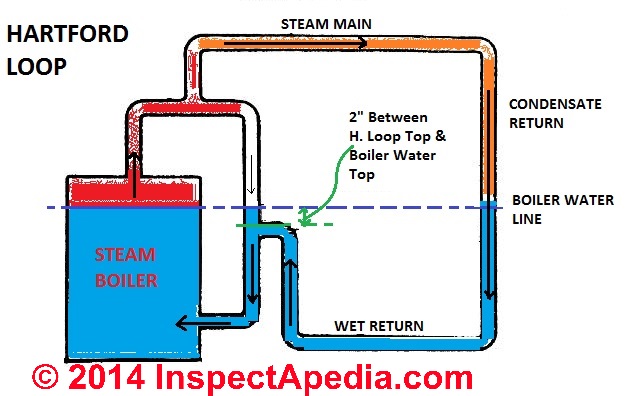

The steam piping (with steam flowing through it) is directed through the flue gas path in the boiler furnace. This area typically is between 1,300–1,600 °C (2,372–2,912 °F ). Some superheaters are radiant type (absorb heat by thermal radiation ), others are convection type (absorb heat via a fluid i.e. gas) and some are a combination of the two. In steam piping layout the top of the Hartford Loop will be located at a height that places it 2" below the water line in the steam boiler. Piping Diagram GC-160 (Discontinued) GC-160 (Discontinued) Piping Diagrams for Model 160 Combi/Heat Only Boiler ... Specification for 28HE Series High … This boiler, gas piping and accessories must be installed, con- ... WIRING DIAGRAMS FOR STEAM BOILERS WITH VENT DAMPER. STEAM (PZ,PZT AND PPZT) BOILER WITH ...20 pages

Hot Water Boiler Piping Zone Valves - Boiler piping zone valves are used for zoning hot water systems where multiple zones are needed.Hot water system zoning can also reduce energy cost because hot water heat zones which are not needed can be shut down thereby reducing boiler runtime to provide hot water heat for those specific zones.. Zoning a hot water boiler system can be done by using ...

0 Response to "40 steam boiler piping diagram"

Post a Comment